We develop advanced manufacturing processes, fixtures, & automated machines, complimented with product design and R&D.

OUR MISSION: TO BUILD CUSTOM MANUFACTURING EQUIPMENT, TEST FIXTURES, & AUTOMATION THAT R&D AND MFG TEAMS LOVE TO USE

HOW TO LEVERAGE US:

From the early stages of R&D through formal device verification and into production, Pipeline partners with your engineering & manufacturing teams to translate user needs into engineering requirements and develop custom manufacturing equipment, turnkey test fixtures, & automated machines that characterize, inspect, assemble, manufacture, & perform verification testing on your devices.

EQUIPMENT, FIXTURES, & AUTOMATION

Benchtop automation, inspection stations, cycle test machines, and much more for accurate and repeatable test & manufacturing operations

PRODUCT DESIGN &

DEVELOPMENT

Mechanical design, industrial design, R&D, and design for manufacturability – everything from medical devices to consumer products

PROCESS DEVELOPMENT AND R&D SERVICES

Our R&D engineers invent new processes to test, inspect, and manufacture your products, then build your production equipment around these processes.

OUR VALUED PARTNERS

TELL ME SOMETHING GOOD.

OUR PORTFOLIO

Design Solution

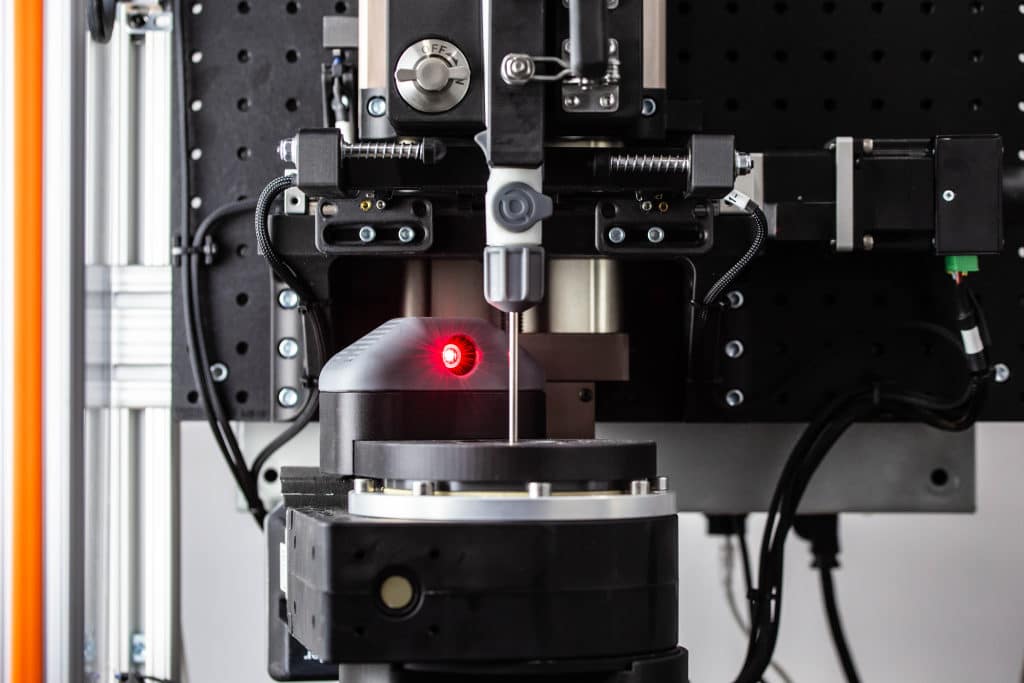

FUNCTIONAL TEST STATION PROJECT SUMMARY

The functional test fixture allows an operator to simply insert and remove a device – the rest of the test sequence is fully automated via a custom LabVIEW program which steps through a multi-button cycle test and a vision system 360-degree scan that can encompass mechanical/quality characteristics as well as operational characteristics (such as RPM, speed, shaft straightness, vibration, and more.)

TEAM:

Mechanical Engineers

Software/Control System Engineer

Electronics/Cabling Engineer

Machinist

Assembly technician

DESIGN TOOLS:

Solidworks 3D CAD

LabVIEW

Design Solution

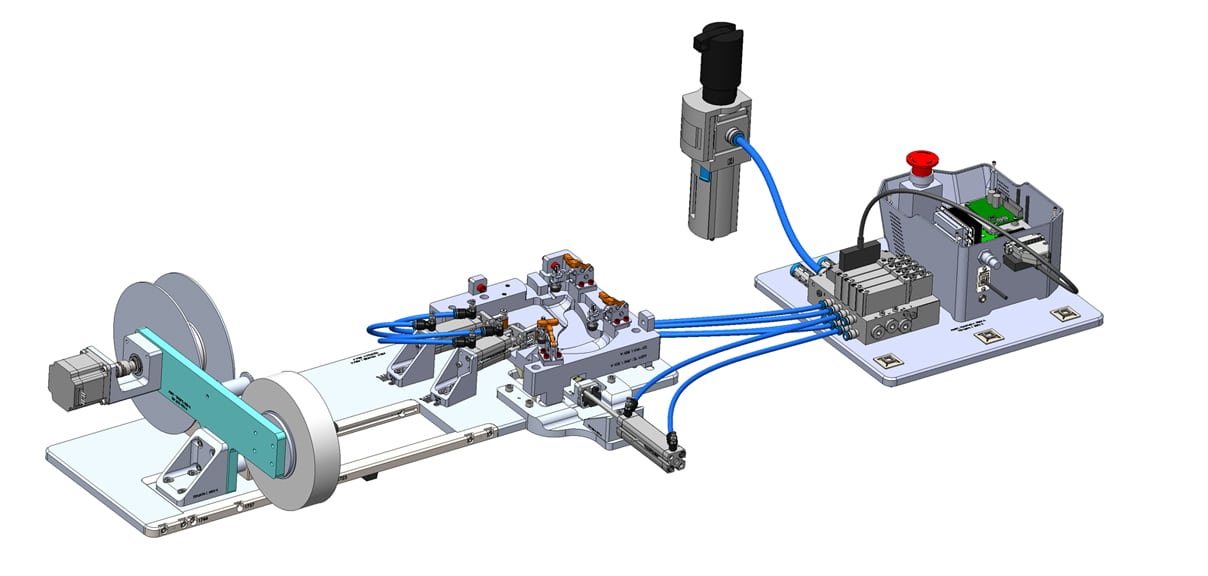

CYCLE TESTER TEST FIXTURE PROJECT SUMMARY

A custom medical device test fixture to actuate multiple mechanisms on a device in an automated manner. The custom program built to control the automation also provided the ability for an operator to easily reprogram the cycle process to alter several key parameters.

TEAM:

Mechanical engineer

Electrical Engineer

Manufacturing Vendor

DESIGN TOOLS:

Solidworks 3D CAD

LabVIEW

McMaster-Carr

Design Solution

MEDICAL DEVICE TEST FIXTURE PROJECT SUMMARY

This project encompassed the design and procurement of a comprehensive set of fixtures for functional and characteristics testing performed on a plethora of optical medical catheters. A total of six requirements-driven fixtures were developed, perfected, and delivered during the life of the project.

TEAM:

Mechanical Engineer

Machinist

DESIGN TOOLS:

Solidworks 3D CAD

DesignX

Markforged 3D Printing

How can we help you?

Contact us today to discuss how we can help!

COMMUNITY