ULTRASOUND CATHETER TEST FIXTURE

PROJECT SUMMARY

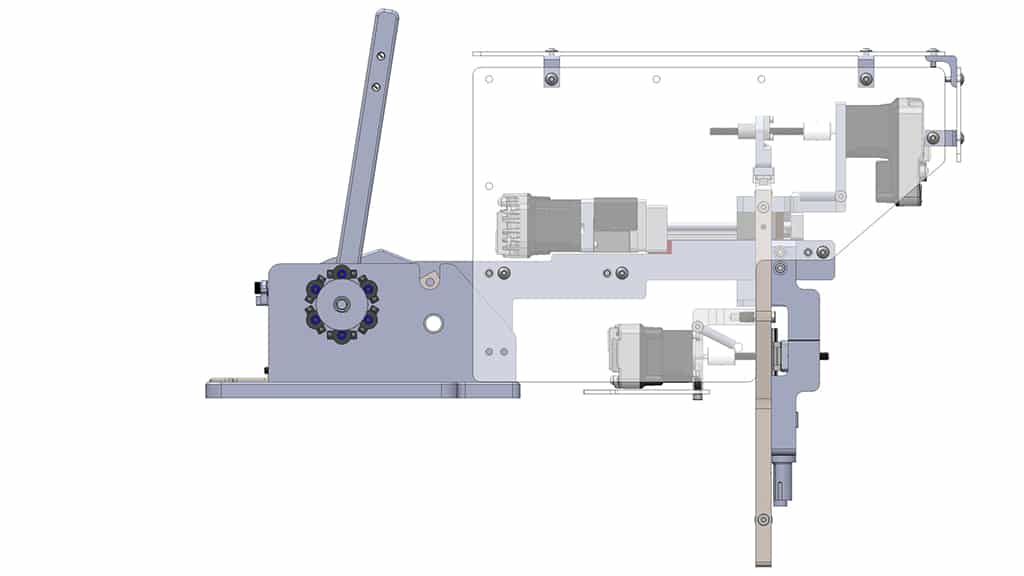

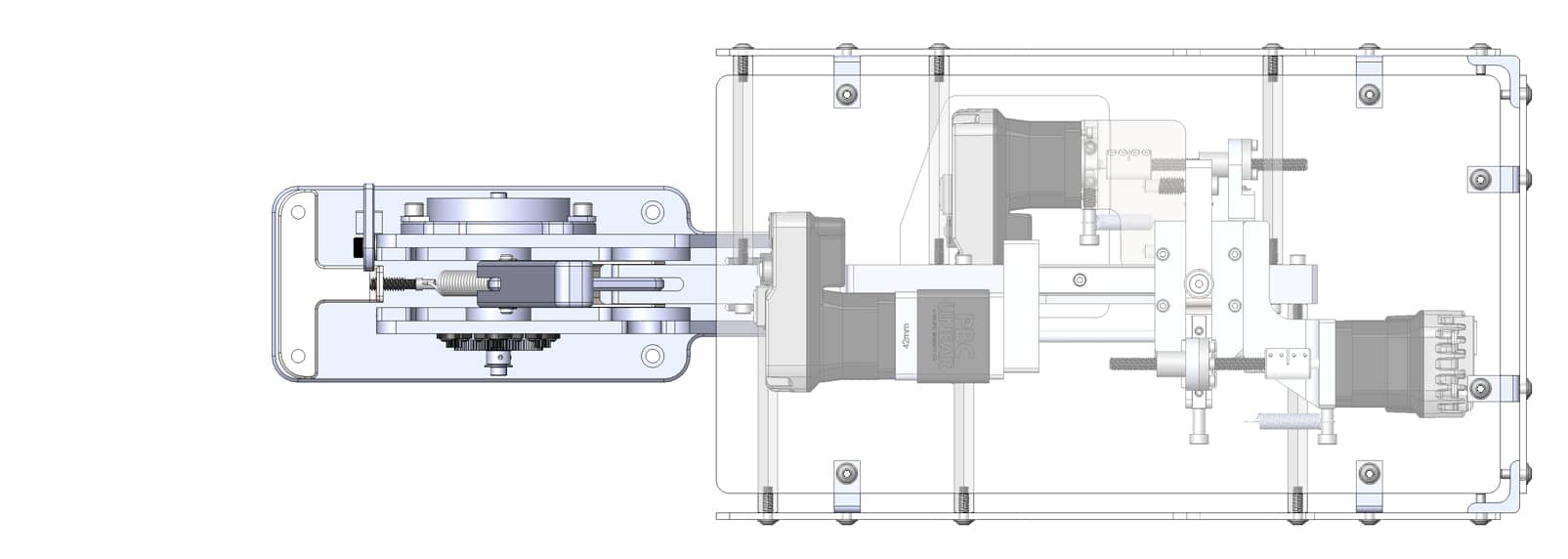

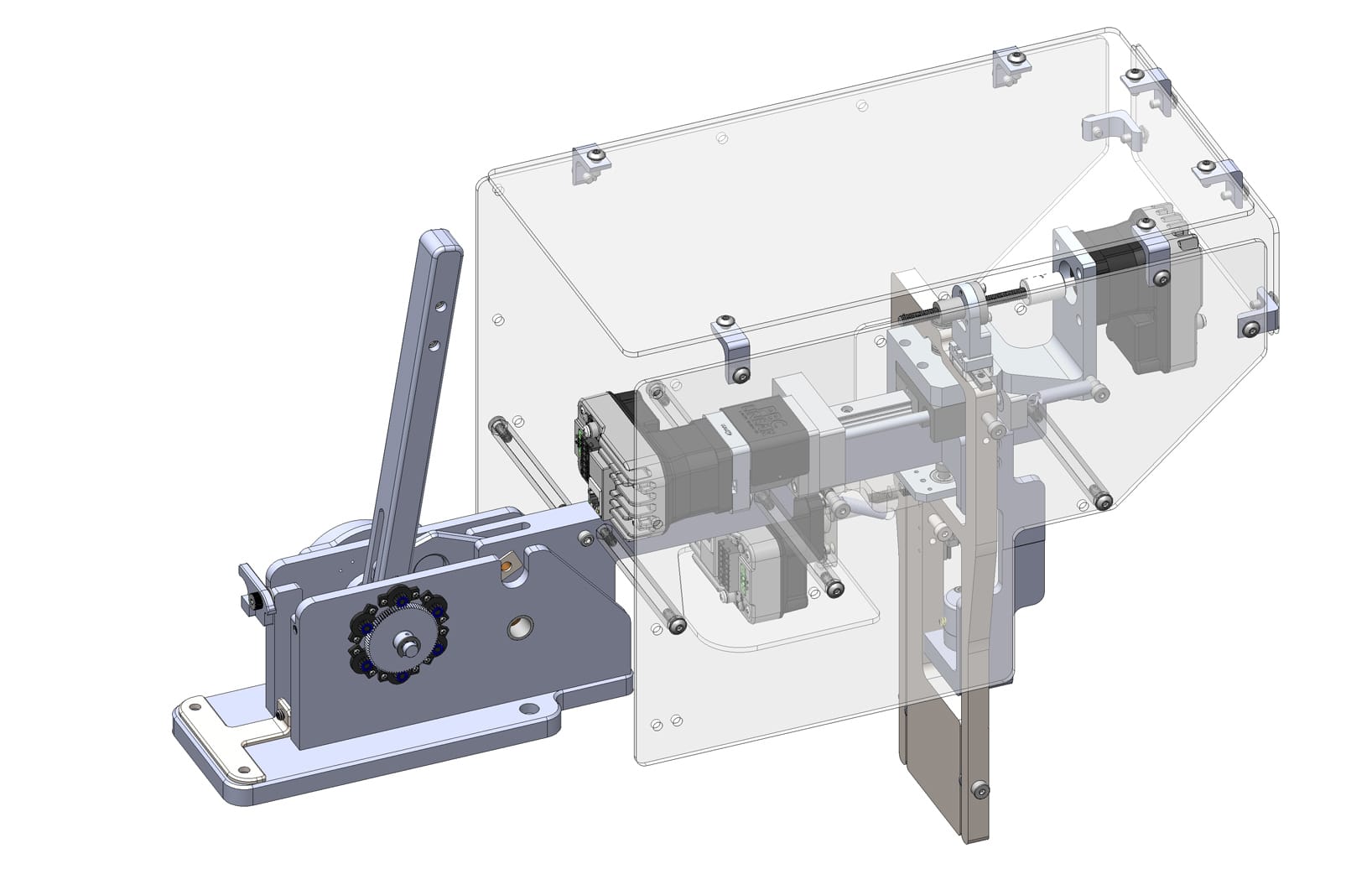

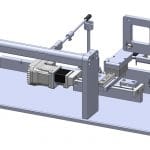

Pipeline Design & Engineering created an ultrasound catheter test fixture that allowed the user to automatically position an echo plate relative to the end of the device under test (DUT)

TEAM:

Mechanical Engineers, Software/Control System Engineer, Electronics/Cabling Engineer, Machinist, Assembly technician

DESIGN TOOLS:

SolidWorks 3D CAD

LabVIEW

MARKET:

Test Fixture, Automation & Motion Control

PROJECT REQUIREMENTS

- Develop LabVIEW program to control motion of fixture

- Move echo plate in 3 degrees of freedom (pitch, yaw, and linear displacement)

- Made from non-corrosive materials to withstand wet environment

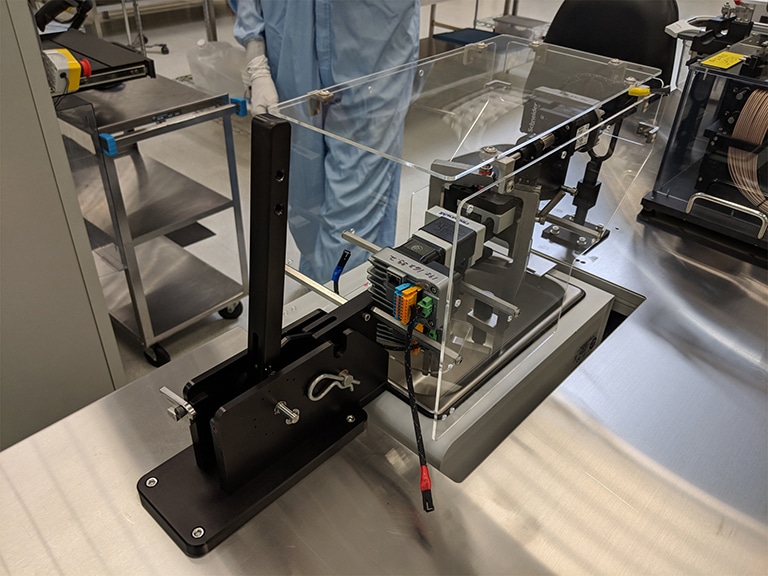

- Mechanism for technician to easily lift functional module of fixture out of bath

SUMMARY OF ACTIVITIES

During their R&D validation phase, Pipeline’s customer had developed a manual process for testing the ultrasound transducer at the distal end of their catheter and now needed to turn this into an automated production process. Pipeline was asked to redesign the mechanical assembly of the ultrasound catheter test fixture and incorporate motors to facilitate the automation of the assembly, as well as provide software programming to drive the motors. Also, some areas of the fixture would be submerged and thus required materials that would not corrode.

Pipeline designed a 3-axis motorized ultrasound catheter test fixture that automated the positioning of the transducer relative to a precision-machined echo plate. The motors controlled pitch, yaw, and displacement via a custom LabVIEW program. The entire system was retrofitted into an existing test bed, and 316L stainless steel components were used to withstand extended use in the corrosive environment. A lift assist mechanism was also incorporated to help operators move the fixture in and out of its functional position. Once the engineering development was complete Pipeline machined the custom components, built the mechanical assembly, wired the electrical system, and installed the fixture on site at the customer’s facility.

How would industrial automation help you advance your projects? Let’s talk!