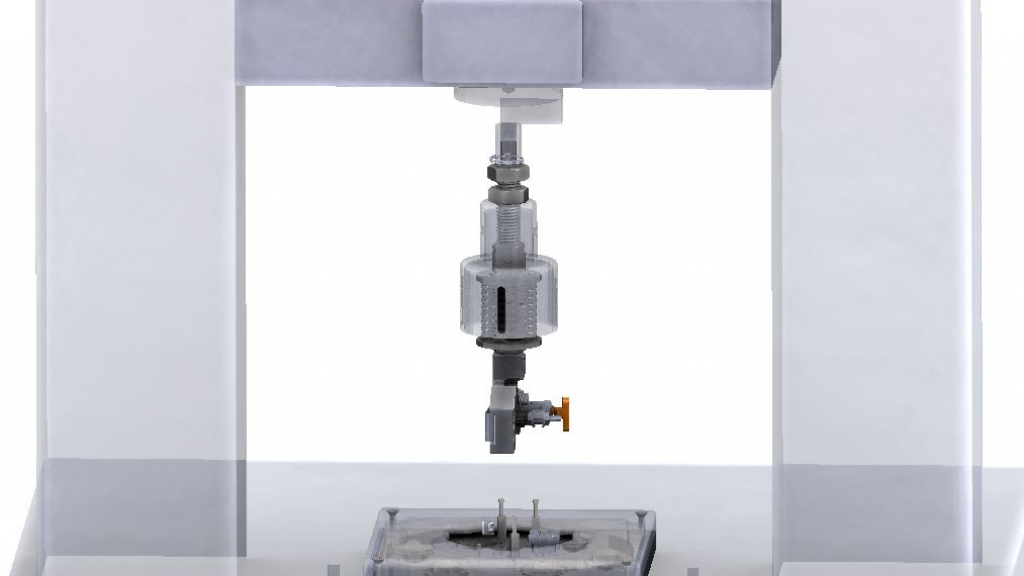

DROP TEST FIXTURE

PROJECT SUMMARY

Pipeline Design & Engineering created a drop test fixture to measure the effects of impact at various connector orientations, and another fixture to measure the unconstrained insertion force on a surgical device connector.

TEAM:

Mechanical Engineer, Machinist, Assembly Technician

DESIGN TOOLS:

Solidworks 3D CAD

MARKET:

Test Fixture

PROJECT REQUIREMENTS

This project included a drop force fixture as well as an insertion force fixture.

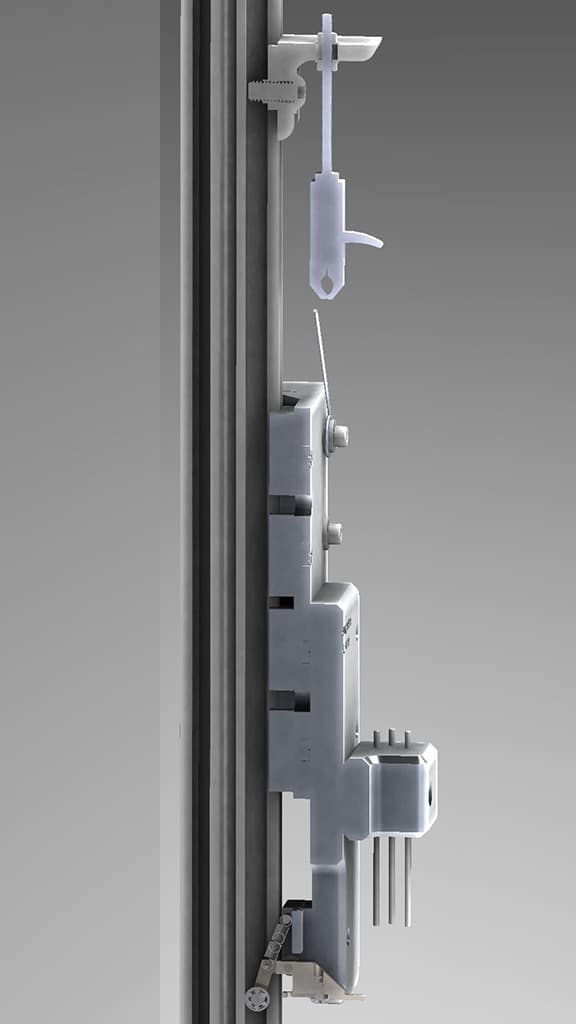

DROP TEST FIXTURE REQUIREMENTS:

- Connector Must be constrained in three separate & interchangeable orientations

- The connector must be held in place until fully accelerated at which point it should be released from the track to impact the surface below.

- The drop speed, drop height, and normal-axis-impact-angle must be adjustable

INSERTION FORCE FIXTURE REQUIREMENTS:

- Connector must be constrained rotationally and translationally (to apply force) about the center axis.

- The connector must have an adjustable amount of ‘auto-centering’ force.

- The base of the fixture must be free to translate and rotate along the ground plane with minimal friction.

- A key and swivel cam combo is necessary to test locked vs unlocked state of the connection

- Fixture must have seamless integration with the current load cell and Instron Machine

SUMMARY OF ACTIVITIES

INSERTION FORCE FIXTURE:

The customer needs to validate the cyclic functionality of a surgical device connector after manufacturing and post-handling treatments. Current fixture capabilities are too constrained for off the shelf hardware and custom hardware must be designed in order to obtain repeatable and reliable data.

Pipeline used collaborative “Master Modeling” and motion-enabled solid modeling techniques to design, review, and ultimately define this complex yet user-friendly solution. Following design, the fixture was rapidly manufacturing via a team of CNC specialists and over-the-counter hardware sources. The fixture was assembled and delivered to the customer within an industry standard ‘short lead time’, enabling the customer to meet scheduled deadlines.

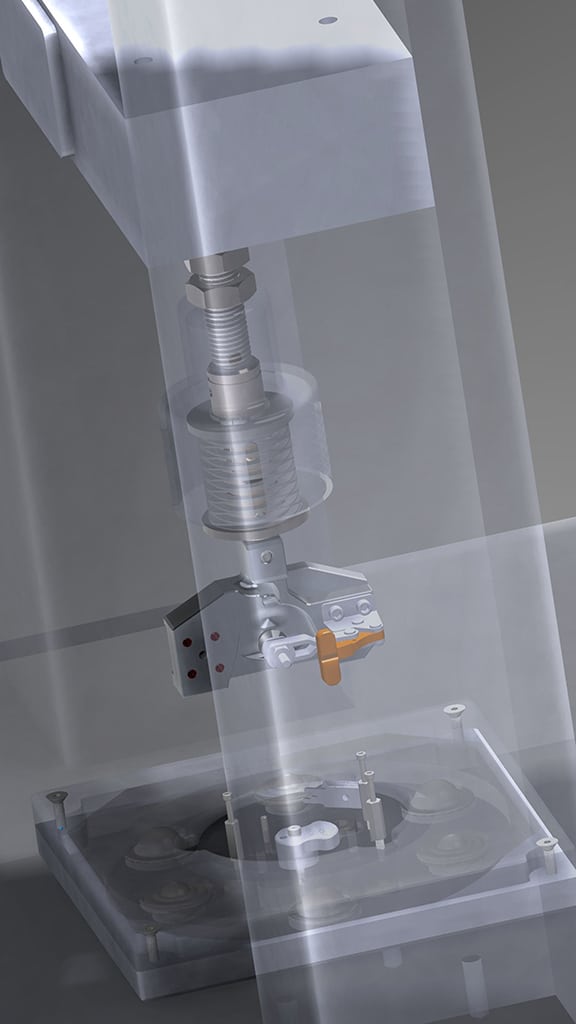

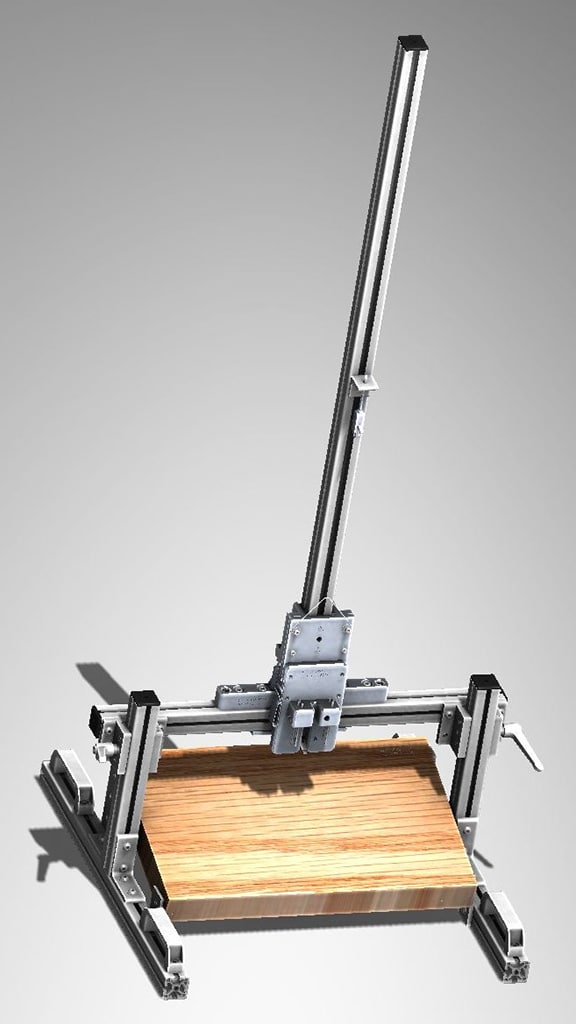

DROP TEST FIXTURE:

The customer needed to repeatedly test and validate the effects of impact on connector functionality at a standardized set of dynamic conditions. Specific care was taken to create a safe and user-friendly environment from which to create and gather aforementioned validation data.

Pipeline used a wide range of off the shelf hardware and solid models to design, review, and ultimately produce this system. Following design, the fixture was rapidly manufactured via a team of CNC specialists and off the shelf hardware suppliers. The fixture was assembled and delivered to the customer within an industry standard ‘short lead time’, enabling the customer to meet scheduled deadlines and take steps towards product goals.

Need help with test fixture design like this? Give us a call!