Catheter Cleaning Fixture

CATHETER CLEANING FIXTURE SUMMARY

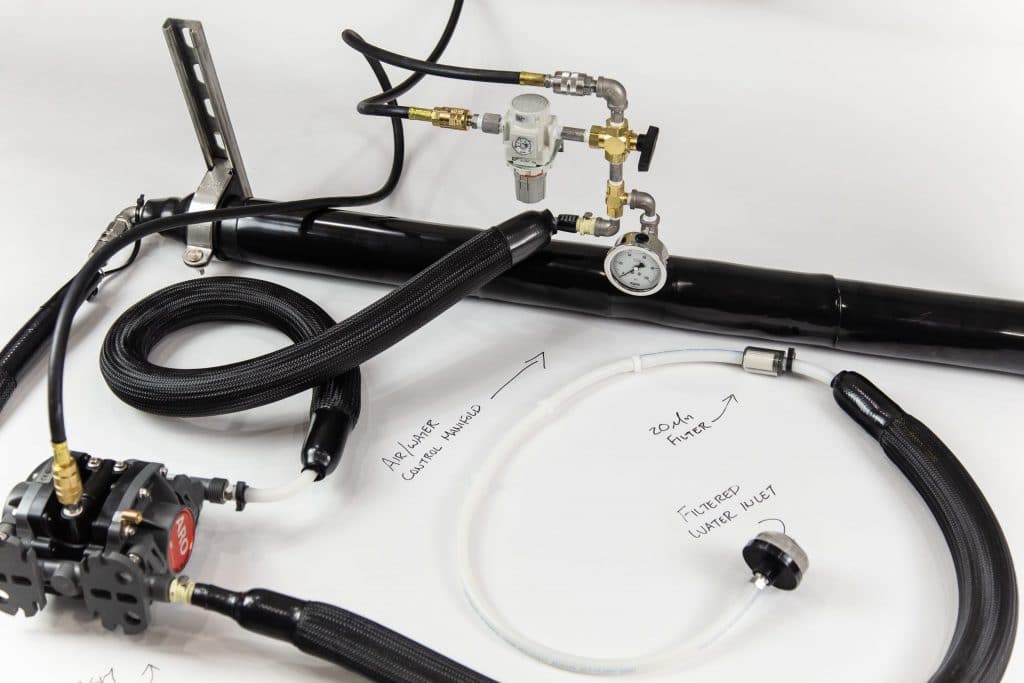

Pipeline Design & Engineering developed a catheter cleaning fixture and process for suitably removing contaminants from catheter microlumens in a production environment.

TEAM:

Mechanical Engineers

DESIGN TOOLS USED:

SolidWorks 3D CAD

MARKET:

Medical Device Reprocessing Equipment

PROJECT REQUIREMENTS

- Create R&D Fixtures to fully define necessary requirements for the catheter cleaning fixture

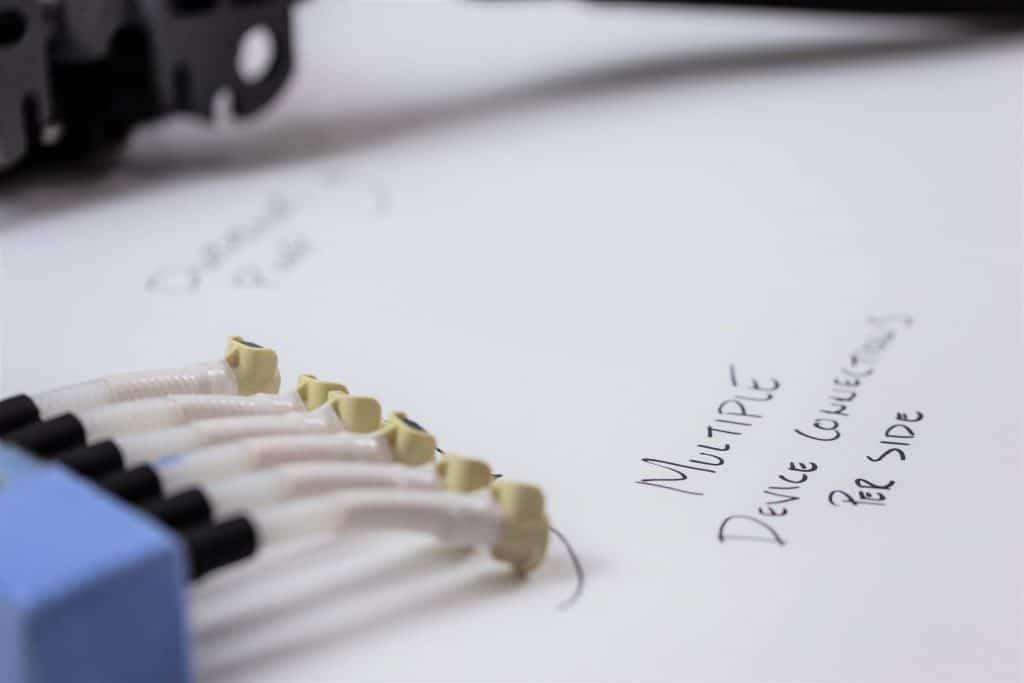

- Create an insulated system for processing 12 catheter devices in a production environment

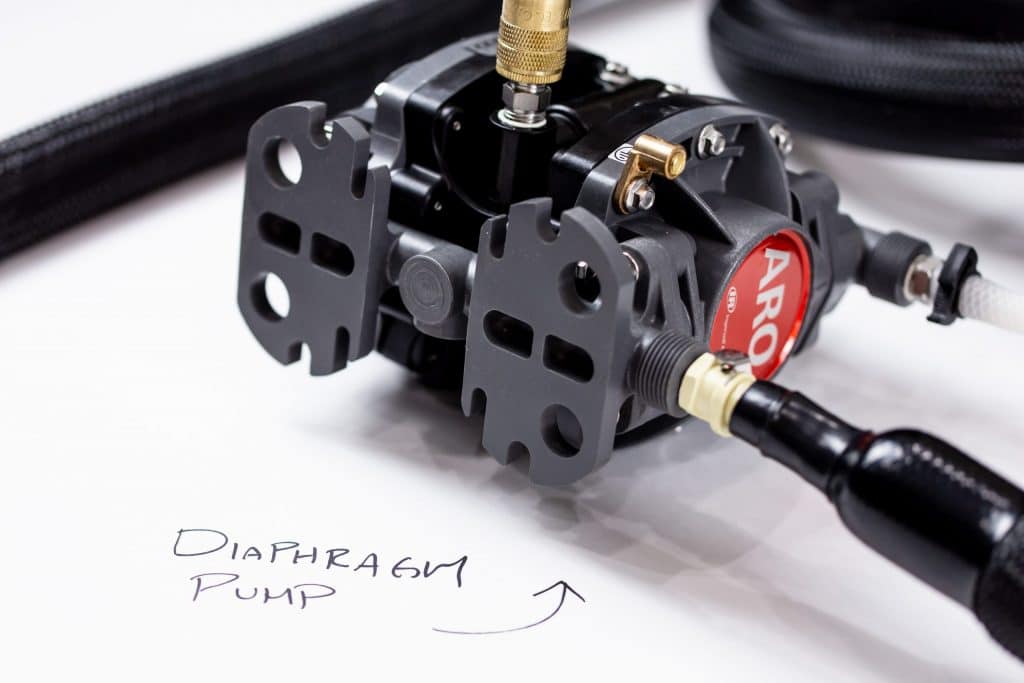

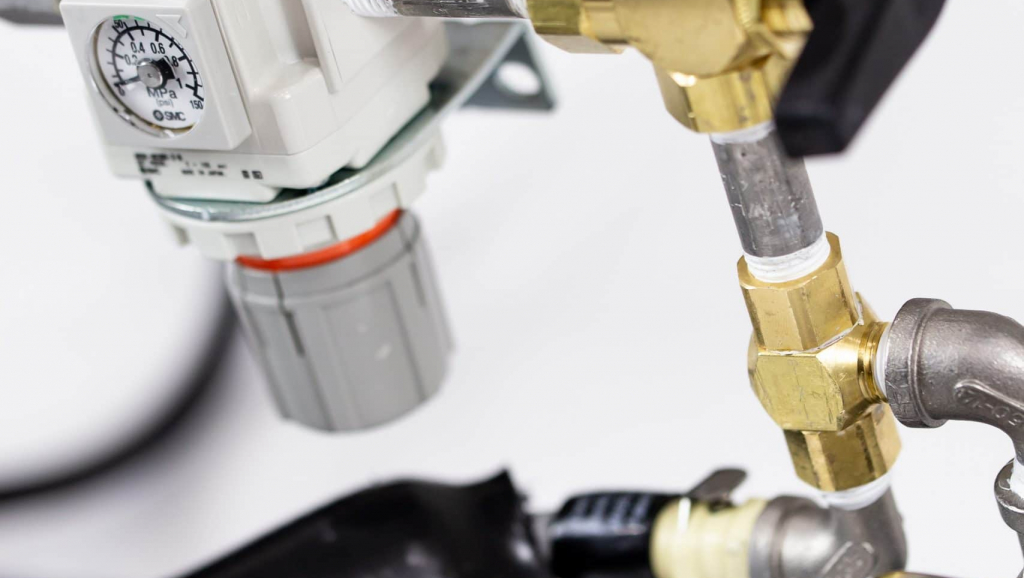

- Hybrid fluid system shall switch from Air/Water supplied at 90PSI (for cleaning and drying operations)

- System shall be made of High-Reliability components capable of sustained cycling and extreme resistance to corrosion and chemicals

SUMMARY OF ACTIVITIES

Pipeline’s customer needed help developing the process and requirements suitable to create a catheter cleaning fixture system to meet their reprocessing team’s cleaning goals. One of the challenges was due to the catheter’s extremely small lumen size (~.010″ ID). After extensive process R&D, was able to develop a process and accompanying hardware to achieve success. Pipeline created multiple configurations of this microlumen cleaning fixture design until the system operating parameters and requirements were fully defined, then designed a reproducible system (detailed in CAD and drawings) for clean-room installation.

Pipeline worked closely with the customer’s engineering team to test and evaluate each component of the catheter cleaning fixture’s functionality and operational characteristics and by so doing produced an optimal solution. Finally, Pipeline designed, procured, assembled, qualified, and installed two of these turnkey systems within a total project lifecycle of roughly two months.

Contact us now to learn how your team can leverage ours to develop test fixture design, equipment, and automation.