CRIMPING FIXTURE for MEDICAL DEVICE

PROJECT SUMMARY

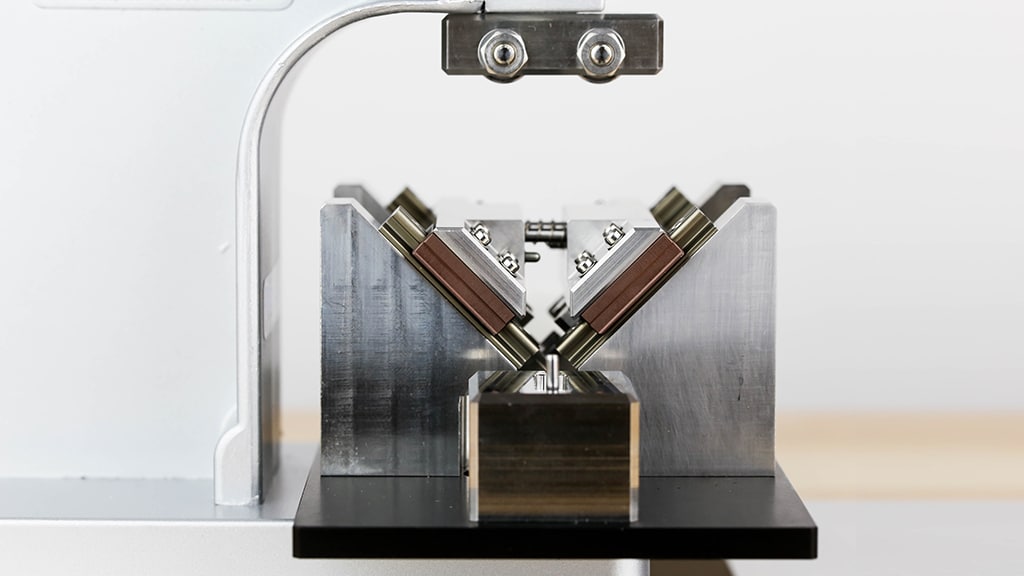

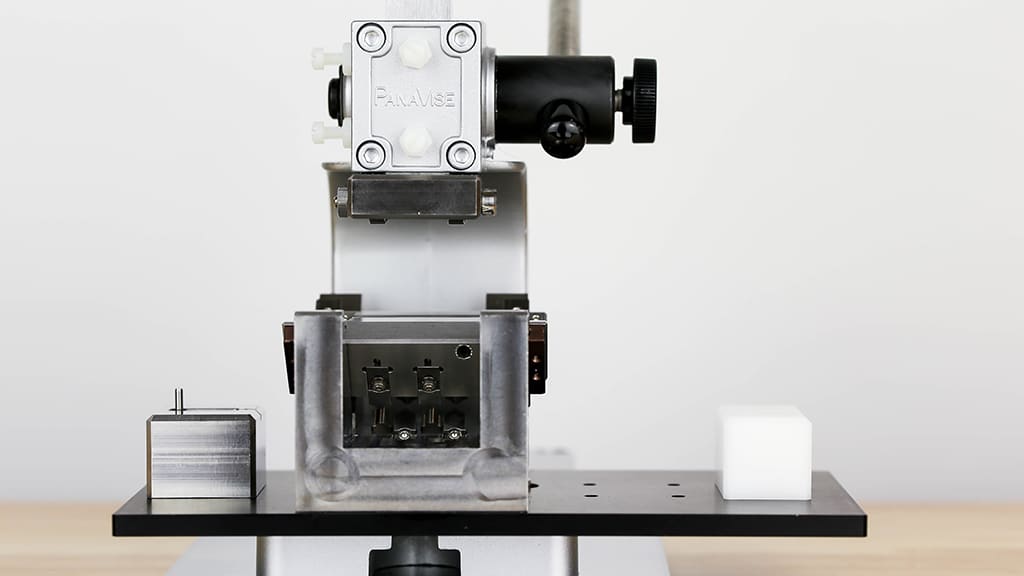

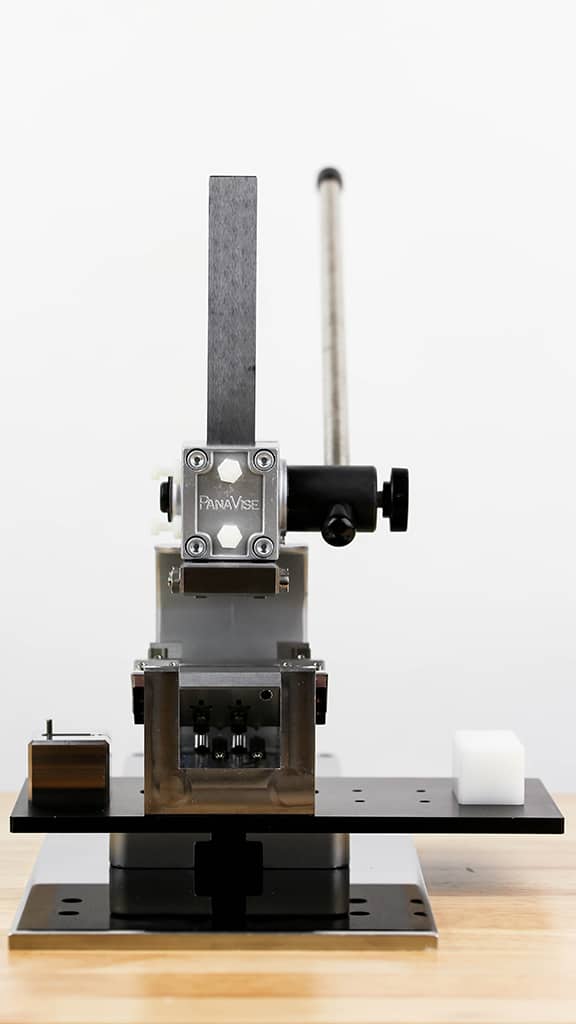

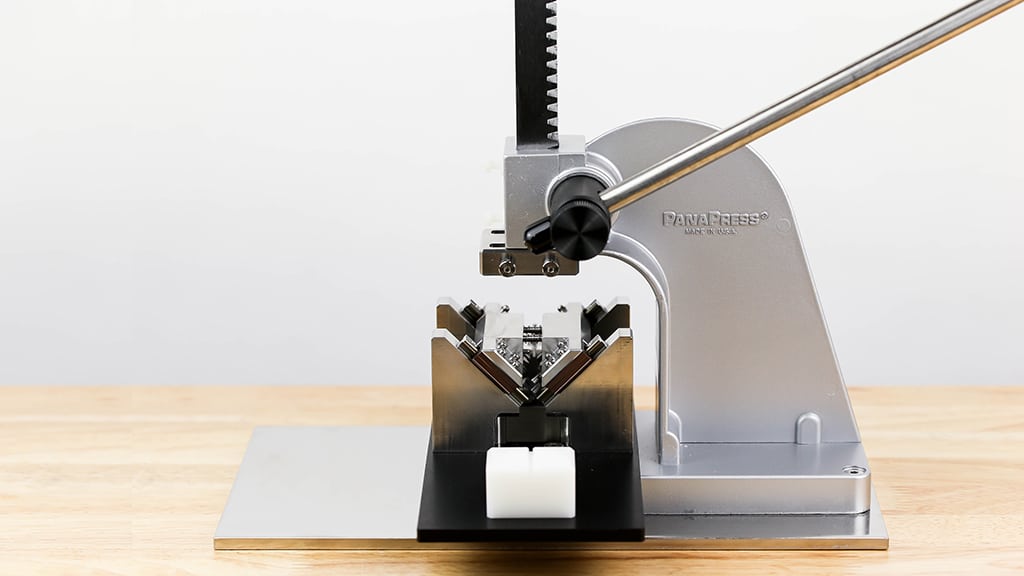

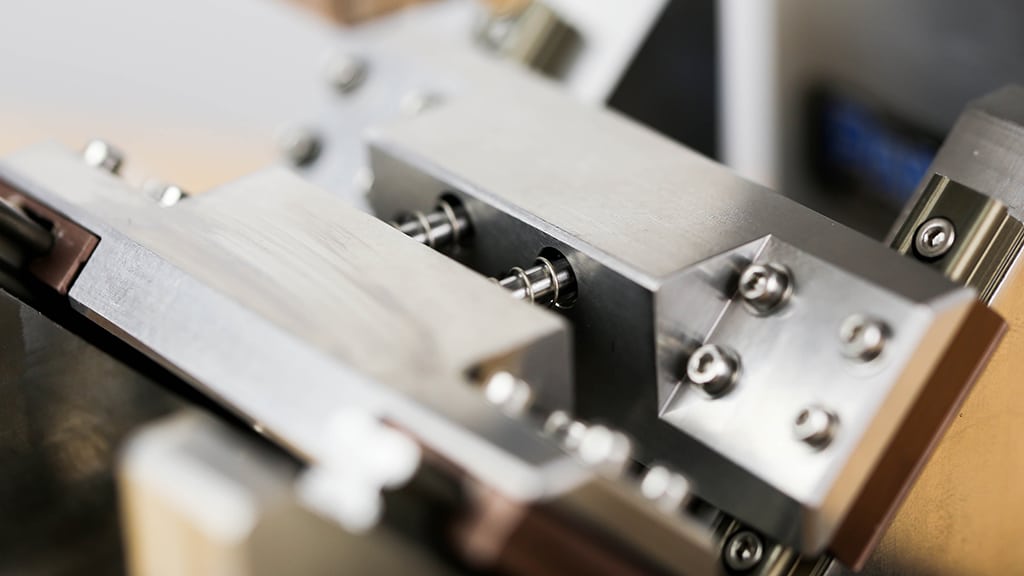

Pipeline Design & Engineering created a fixture to quickly crimp a snare inside of a hypotube for a medical device.

TEAM:

Mechanical Engineer, Machinist, Assembly Technician

DESIGN TOOLS USED:

SolidWorks 3D CAD

MARKET:

Test Fixture

PROJECT REQUIREMENTS

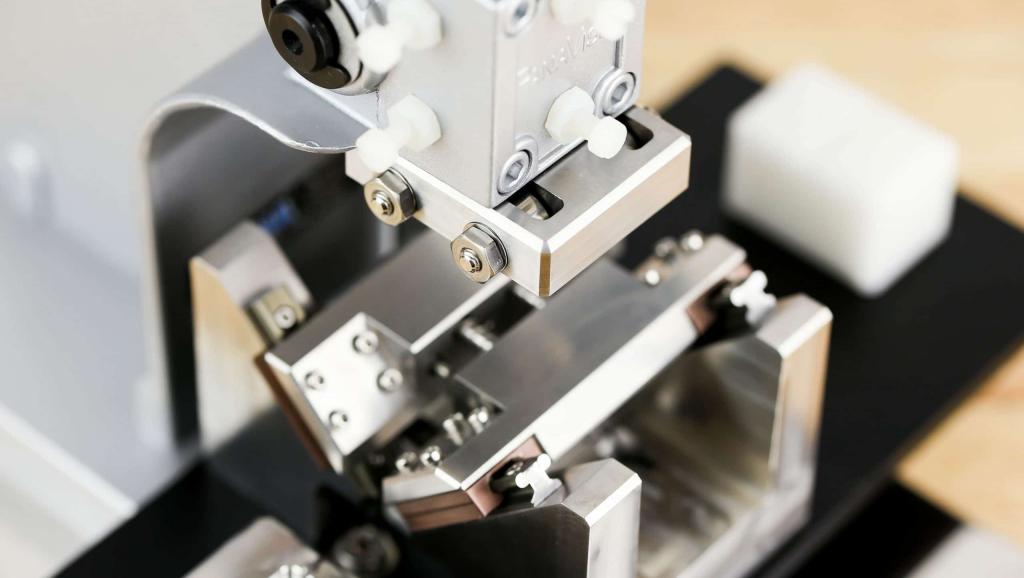

- Crimp a hypotube in four separate areas at the same time with enough force to reliably hold a snare inside the tube

- Incorporate mechanical advantage to ease the effort of the operator

- Work with an existing off-the-shelf arbor press to build the fixture

- Spring load the mechanism so insertion/removal of the snare assembly is simple for the operator

SUMMARY OF ACTIVITIES

A medical device manufacturer approached Pipeline about designing a crimping fixture that would allow their assembly workers to perform a crimping operation with greater repeatability and in less time than their current method. Pipeline provided several conceptual designs to the customer until one was selected to pursue for full development.

Pipeline prepared the detailed engineering design of the chosen concept and built a prototype. The customer approved the prototype and Pipeline built and delivered an additional two assembled units. Each crimping fixture was precisely calibrated to place strong crimps in the same area of the hypotube each time. Additionally, the spring loaded mechanism created a convenient opening around the crimped device which allowed operators to remove the device without interference. These fixtures allowed each operator to complete hundreds of products where previously they were restricted to only a couple of dozen.

Have a test fixture design project? Let’s talk!