PRODUCT LIFECYCLE TESTING

what is product lifecycle testing?

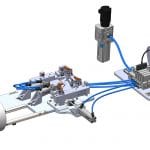

Product lifecycle testing (also referred to as warranty testing, accelerated lifecycle testing, cycle testing, etc) is a processes that uses special equipment to allow R&D, engineering, and manufacturing teams to repetitively cycle an action on a product and determine if or when the corresponding element on that product will fail. For example, if there were a living hinge in a plastic injection molded part, one might employ product lifecycle testing to flex that living hinge and determine how many times it can bend before failure. Or, perhaps a team needs to touch a capacitive screen to determine if it will hold up against hundreds of thousands of touches. There are nearly limitless applications for product lifecycle testing.

OEMs often use lifecycle test fixtures in the R&D or functional verification stages of product development. In this way, these teams can verify that the critical elements of their product will not fail prematurely. It is often the case, as well, that the only way to determine the life expectancy of a product feature or component is to lifecycle test it with such a machine. A few examples of lifecycle testing include the following:

- Actuating a device’s trigger or lever (e.g. laparoscopic instrument)

- Inflating and deflating a pressurized bladder (e.g. medical tourniquet)

- Simulated product motion to measure component wear (e.g. rifle bolt carrier)

From a business standpoint, product lifecycle testing is critical in determining for how long a product should be warrantied. If a product warranty is too long (extending beyond the point at which products’ features will begin to fail), OEMs may lose enormous amounts of money servicing or replacing products that have failed and are still under warranty. Lifecycle testing provides data that OEMs can then use to determine appropriate warranty periods, drastically reducing their risk exposure.

Due to the nature of these tests, the number of cycles run will often exceed 100,000 or more, and so it is impractical to have a human performing the cycle actuations (this can and has led to repetitive stress injuries and thus quickly becomes a health hazard for technicians doing the testing). For this reason some level of automation is usually employed in product lifecycle testing, often in the form of pneumatic actuators, robots, or motors producing linear or rotational motion.

Pipeline has developed many custom life product lifecycle testing machines, systems, & fixtures over the years, from simple button-pusher cycle testers to sophisticated automation that not only performs the cycle testing but also load and reload consumable components so that the overall system can continue to be tested for long-term endurance. The automation employed in this testing also allows our machines to acquire data associated with the testing (e.g. # of cycles, force data, pressure data, cycle time, total test duration, etc).

Need some Product

Lifecycle Testing?

Pipeline Design & Engineering provides product lifecycle testing services

to established product companies, startups, inventors, and any other groups

with warranty testing needs. Please contact us today and let’s get started!