AUTOMATED CARTON ERECTOR

CUSTOM CARTON ERECTOR SUMMARY

A fully automated machine for erecting flat cartons and folding the carton tabs closed to prevent repetitive stress injuries in operators.

TEAM:

- Mechanical engineers

- Controls engineer

- PLC programmer

- Assembly technician

DESIGN TOOLS USED:

- Solidworks

- PLC programming software

- Calibration and qualification tools

MARKET:

Medical device packaging

PROJECT REQUIREMENTS

- Erect and fold tabs of multiple sizes of flat cartons

- Cycle time of less than 16 seconds per carton

- Feed two assembly lines

- Can be run via HMI touch screen

- Multiple security levels for operators & engineer access

SUMMARY OF ACTIVITIES

Operators at the packaging facility were sustaining repetitive stress injuries due to the repetitive nature of erecting cartons and folding tabs closed. Pipeline was engaged to develop an automated machine to perform these activities, and that did so within a cycle time frame that did not reduce the operators’ throughput.

While carton erecting machines already exist commercially, the specific size and shape of the customer’s cartons was unique enough that no off the shelf solutions existed that would accommodate them. Thus, a custom automated solution was required. To further increase the complexity of requirements, the machine had to accommodate vastly different shapes and lengths of the customer’s cartons. In the end, Pipeline developed a solution that not only accommodated the required cartons, but also accommodates a wide range of add’l shapes and sizes should the customer introduce new cartons in the future.

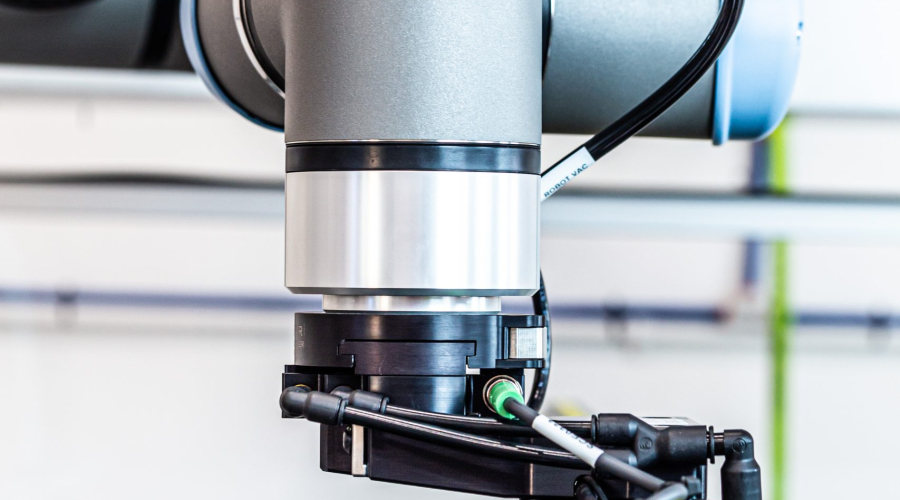

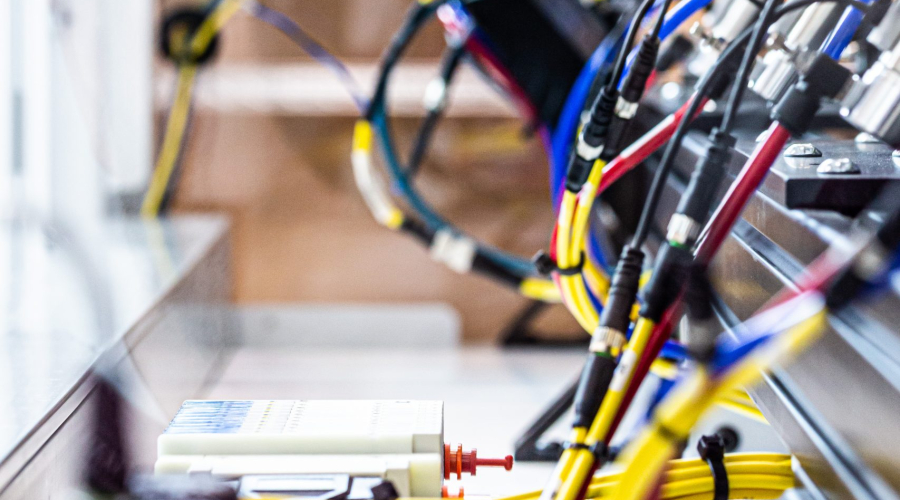

The first phase of the project involved process R&D to develop a routine that reliably performed the erecting and tab folding operations, and that could be automated. Once the process had been verified using manual benchtop mockups, the design was migrated into an automated version using a UR10e robot, multiple air cylinders, motors, and sensors all controlled via a PLC and HMI interface.

The custom carton erector was built and extensive testing and refinement were performed to ensure the machine met its functional requirements per the customer’s URS (user requirements specification). Once the machine had been qualified internally, the customer performed an FAT (factory approval test) to confirm functionality.

Learn about other ways your team can leverage ours to develop custom equipment, fixtures, and automation.