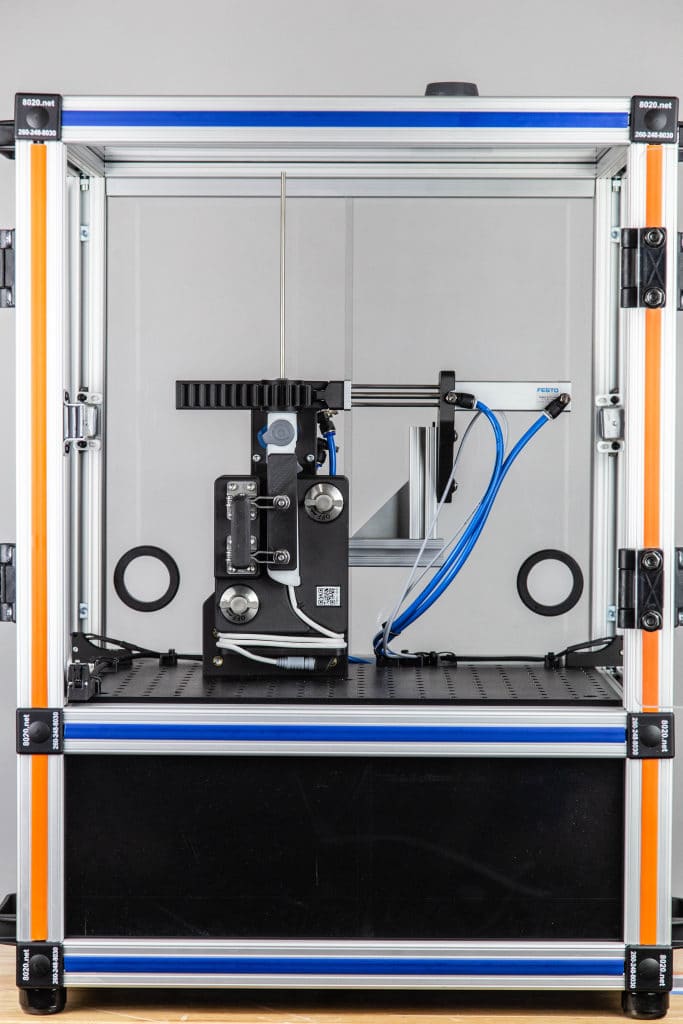

Cycle Test Station

CYCLE TEST STATION SUMMARY

An automated machine for lifecycle testing the mechanical components of a medical device.

TEAM:

Mechanical Engineers, Software/Control System Engineer, Electronics/Cabling Engineer, Machinist, Assembly technician

DESIGN TOOLS USED:

Solidworks, LabVIEW

MARKET:

Medical Devices

PROJECT REQUIREMENTS

- The fixture (cycle test station) must have an operator safety system

- The fixture shall have a safety system to prevent damage to the device

- The system shall have the ability to repeatably actuate the device toggle

- The system shall have the ability to repeatably rotate the device knob

- The system must use compressed air as a power source

SUMMARY OF ACTIVITIES

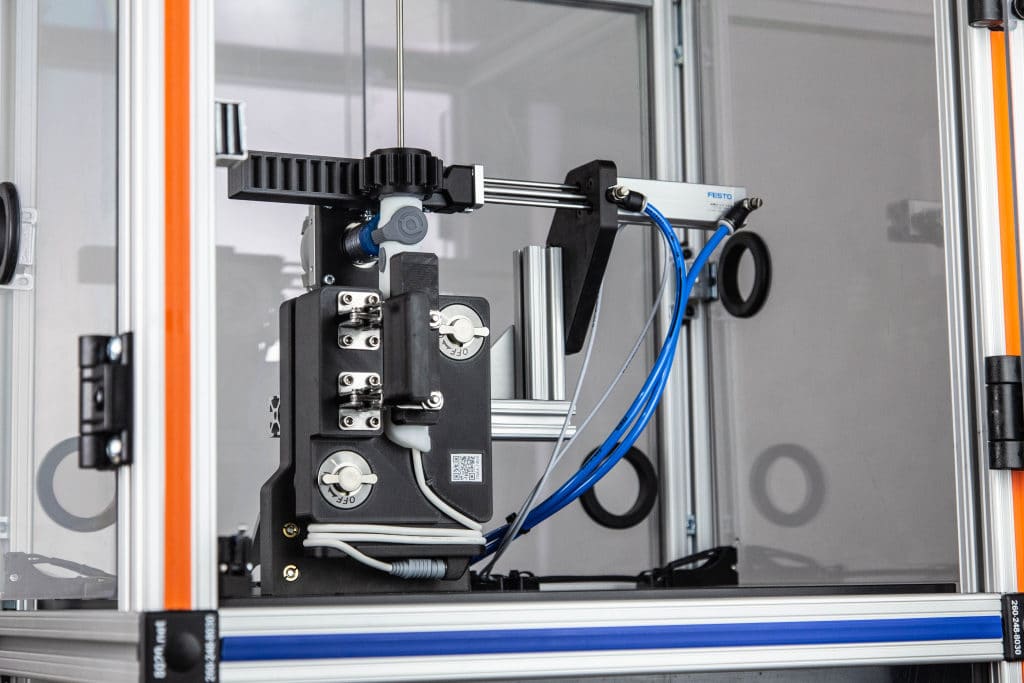

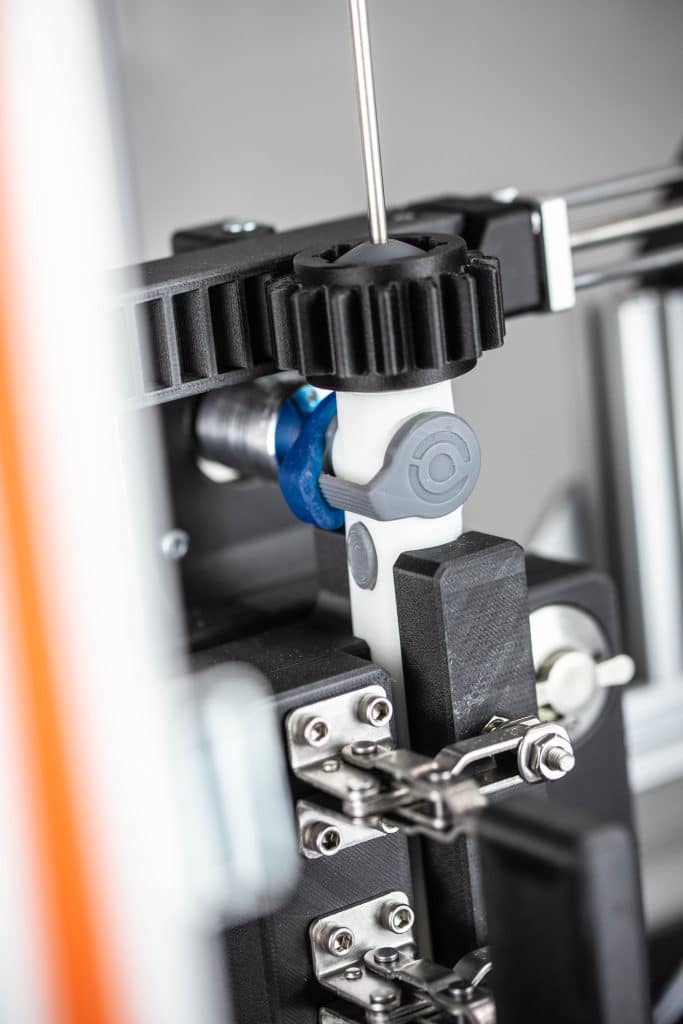

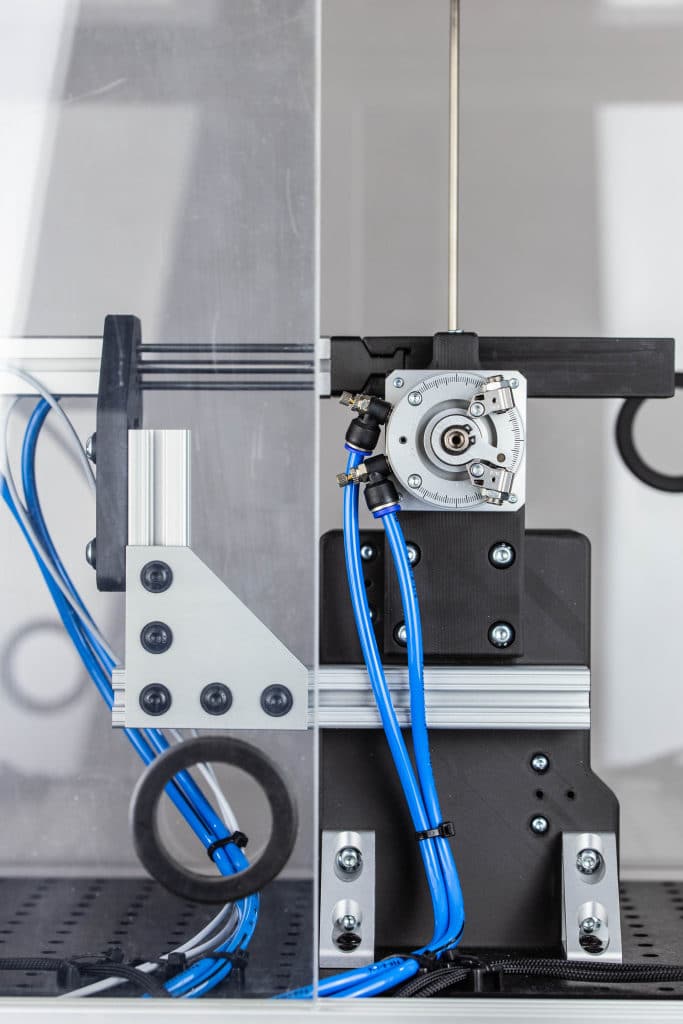

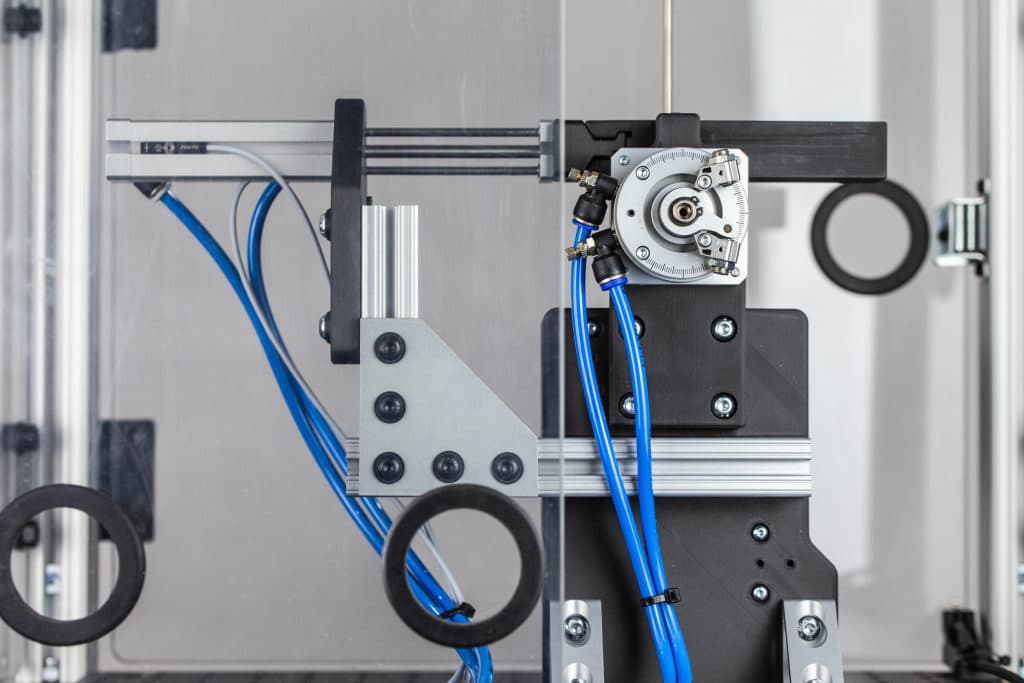

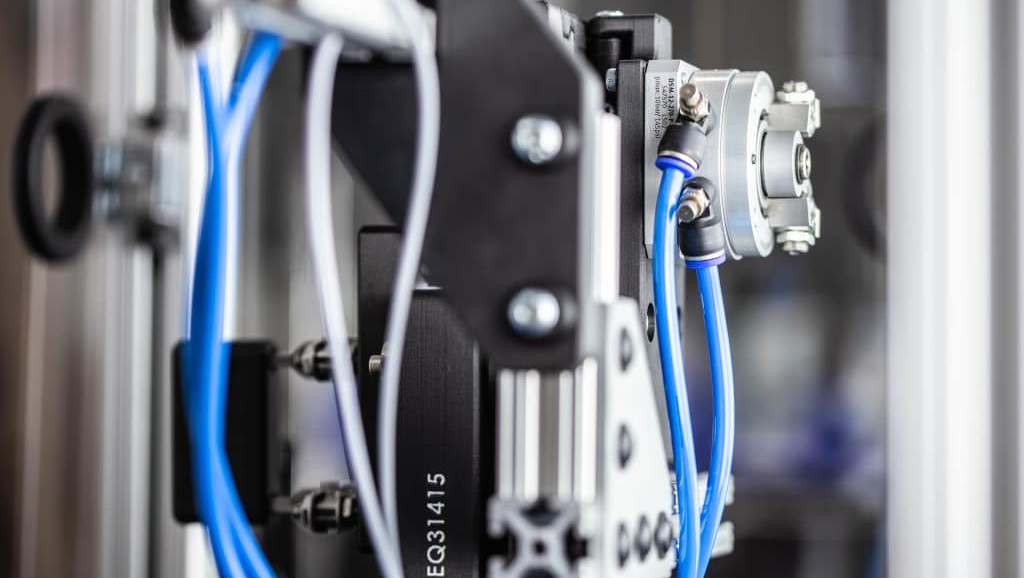

Designed with safety, repeatability, and flexibility in mind, cycle test station is a fully automated pneumatic system operated over MODBUS TCPIP. This modular fixture can accept multiple devices or device families simply by adapting and 3D printing modular device holders, button grips, and collar grips. As shown, the cycle fixture uses a linear air cylinder attached to a rack and pinion to cycle the medical device collar, and a rotary air cylinder to cycle the action-on/action-off button. Pipeline’s proprietary “SMC” (simple motion control) software easily allows users to edit, save, and load various sequences and keep track of vital information such as cycle time and safety status.

Activities performed during this cycle test station development project included the following: Preliminary Design, Preliminary Software Development, Internal Design review meetings, Detailed Design, Final Design, Manufacturing, Assembly, Final software development/build/compile, Internal Test and Validation

Cycle testing is a common practice adopted by manufacturers to ensure their devices do not fail prematurely. Having an operator manually cycle a device hundreds or thousands of times is expensive, impractical, and potentially unsafe for the operator (repetitive stress injuries) and thus an automated solution such as this is the most attractive method for manufacturers to reduce risk and ensure an acceptable lifecyle of their product.

Need support with test fixture design? That’s our specialty! Contact us today.