Automated Test System

AUTOMATED TEST SYSTEM SUMMARY

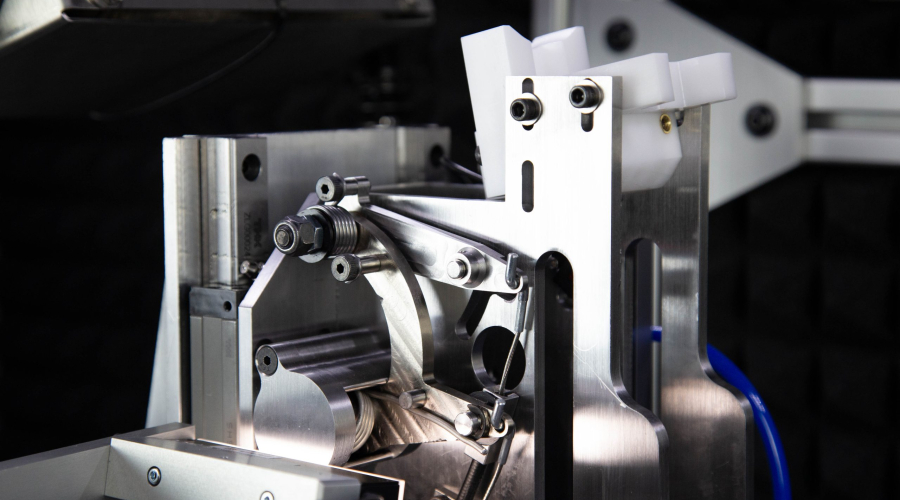

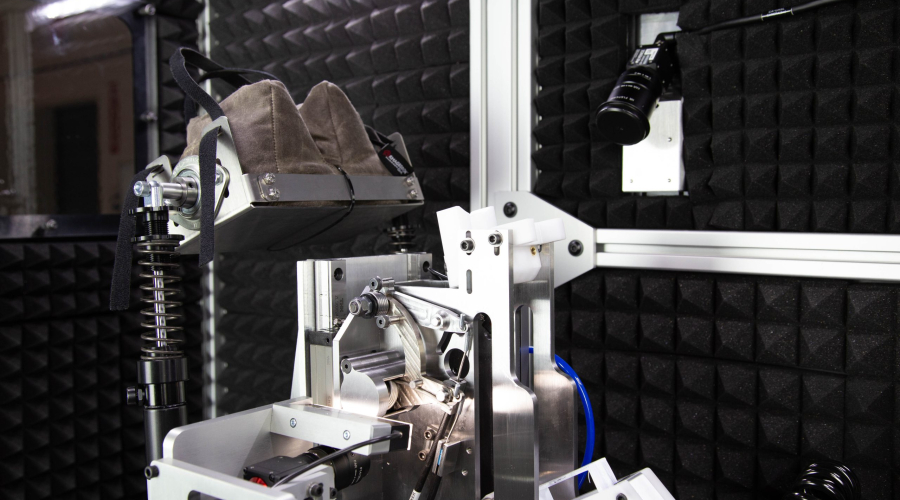

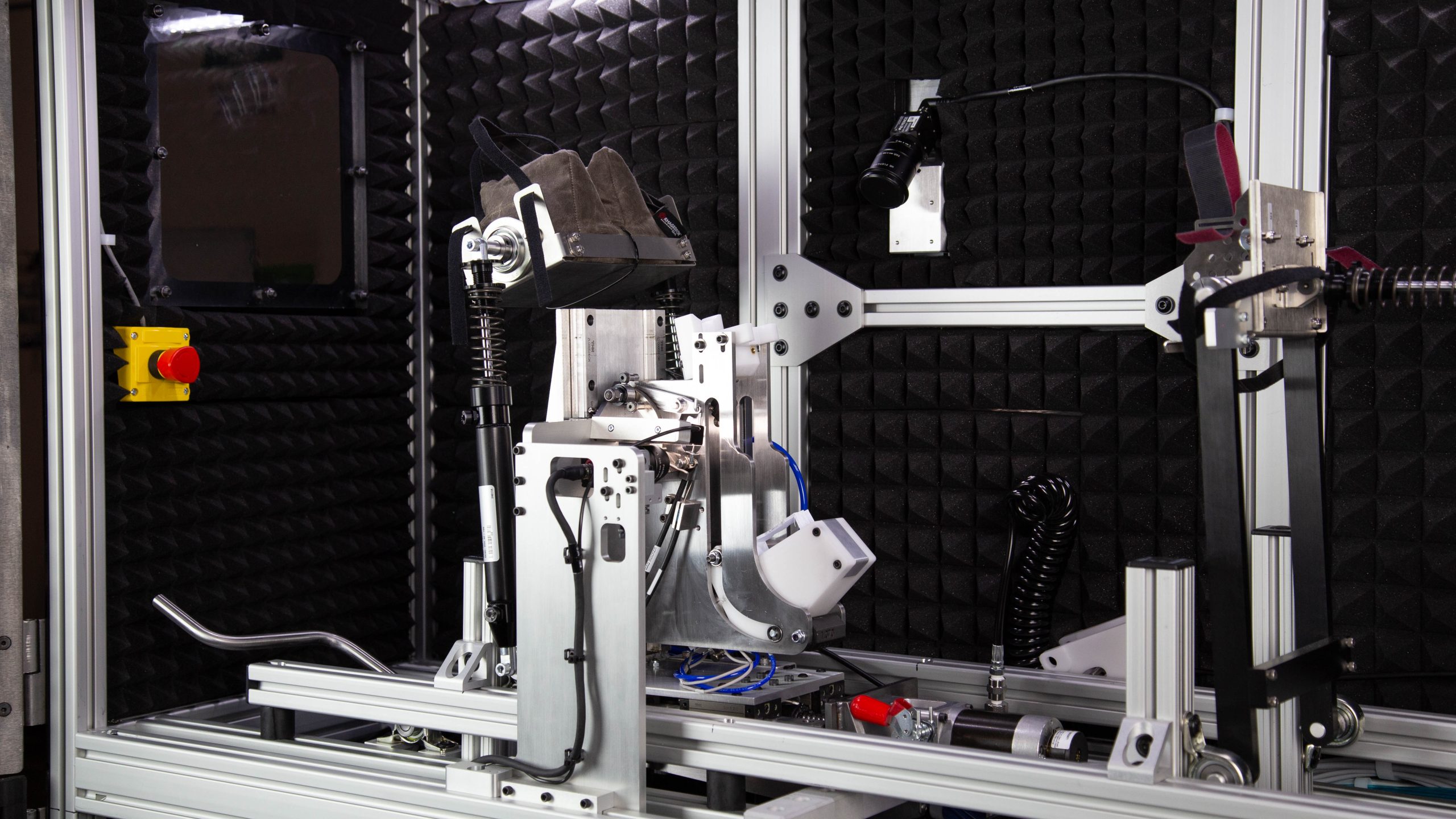

Utilizing dual pneumatic air supplies, our custom design accurately replicates external user forces, accommodating two product variations, and interfaces with DUT reset, all within an 80 dB noise level.

TEAM:

- Project Lead

- Mechanical Engineer

- Designer

- Software Developer

- Assembly Technicians

DESIGN TOOLS USED:

- Solidworks

- Visual studio

- Python programming

- Integrated Keyence Software

- Galil Design Kit

MARKET:

Test fixture, automation, and controls

PROJECT REQUIREMENTS

- Dual pneumatic air supplies

- Accurately replicate external reaction forces generated by user in a typical use case

- Dual custom design to accommodate two product variations

- Interface with DUT reset component for continuous testing sequence

SUMMARY OF ACTIVITIES

The project involved designing and performing sequential actions on two variations of customer products. We successfully replicated external forces with variation and interfaced with components on both DUT’s, establishing a continuous testing loop with in-process feedback.

Learn about other ways your team can leverage ours to develop custom equipment, fixtures, and automation.