Deflection Force Tester

DEFLECTION FORCE TESTER SUMMARY

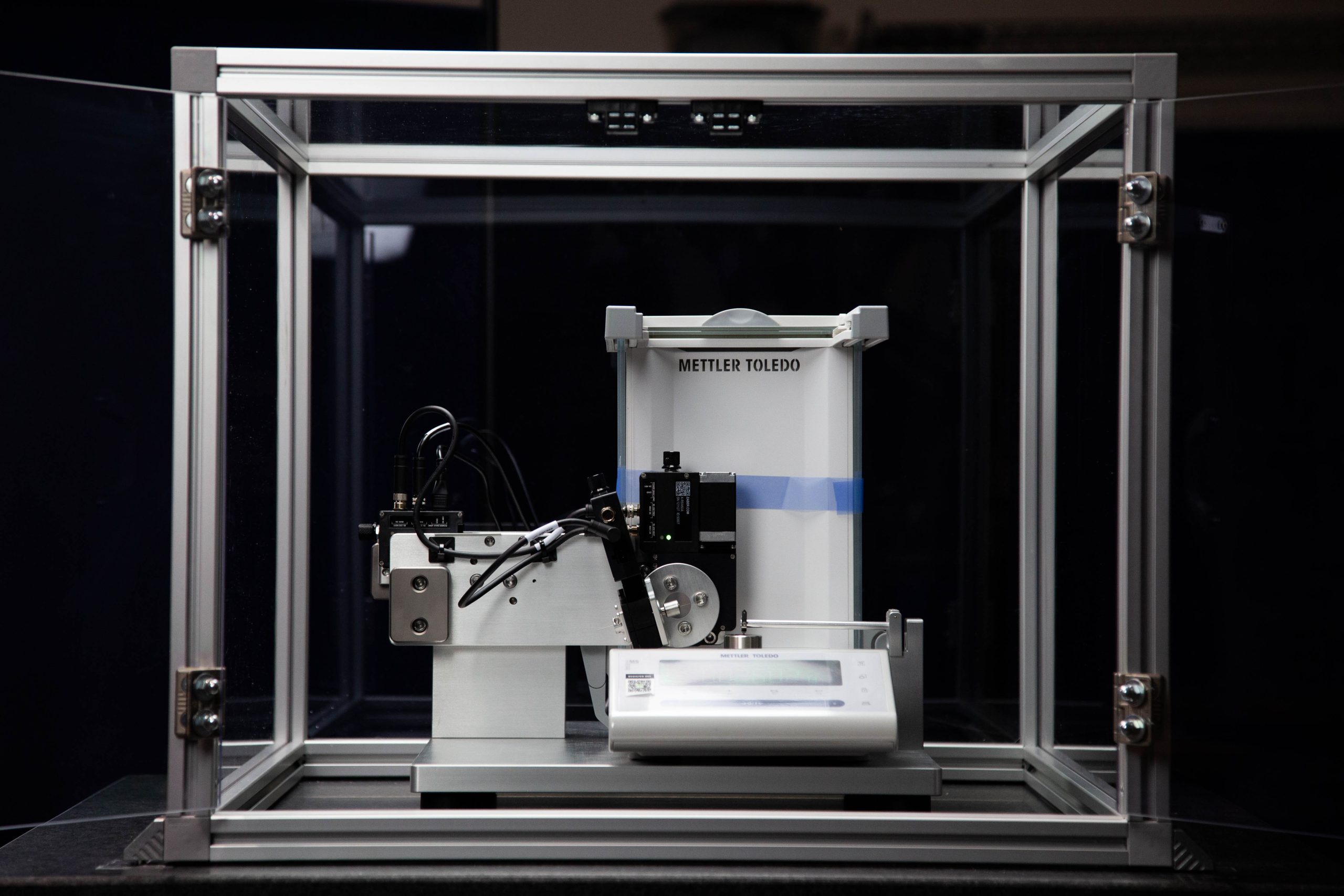

Re-designed as a fully automated system, this test system precisely measures deflection force applied to custom wire sizes and materials.

TEAM:

- Project Lead

- Project Manager

- Engineer

DESIGN TOOLS USED:

- Solidworks

MARKET:

Healthcare/medical device manufacturing

PROJECT REQUIREMENTS

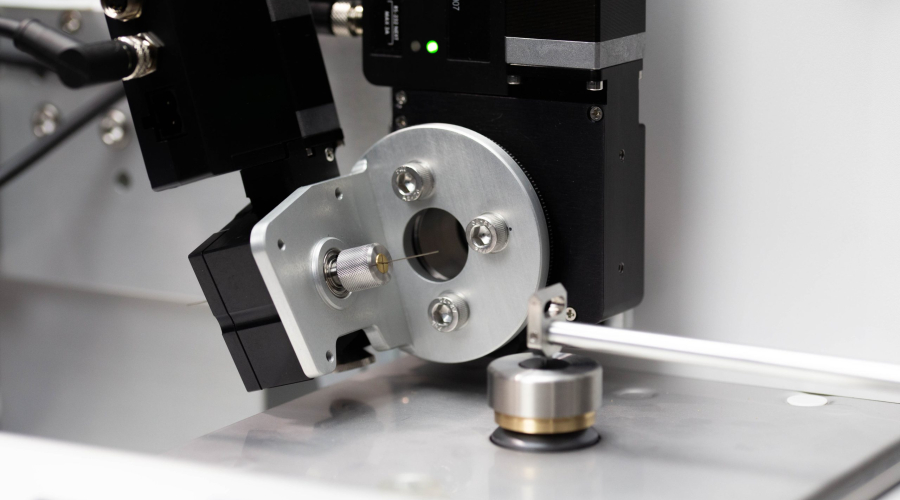

- Collet designed to accept a range of wire 0.01” to 0.035”

- Automatically index to three positions

- Programmable deflection angle (from 1 degree to 20 degrees) and distance from rotation point

- Force measurement to tenths of a micro-gram

- Integrated to run in LabView

SUMMARY OF ACTIVITIES

This test fixture utilized a variable lever-arm cantilever system designed to measure the force applied to various deflection points. We added in-process feedback and automation features, eliminating the need for operator manually adjust the device during validation.

Precision was achieved with Zaber rotary and linear actuators and a Mettler Toledo scale with custom modifications. Encoders were added for precise measurements, ensuring accuracy with wire sizes of up to 0.030”.

Force measurements to hundred thousandths of a gram were attained, minimizing environmental effects on our granite slab. Increasing accuracy and repeatability, the system was enhanced with in-process feedback, automation, and the ability to customize the wire length and deflection points, eliminating the need for manual adjustments. The hardware seamlessly integrated with LabView for user-friendly operation.

Learn about other ways your team can leverage ours to develop custom equipment, fixtures, and automation.