Design Solution

PROJECT SUMMARY

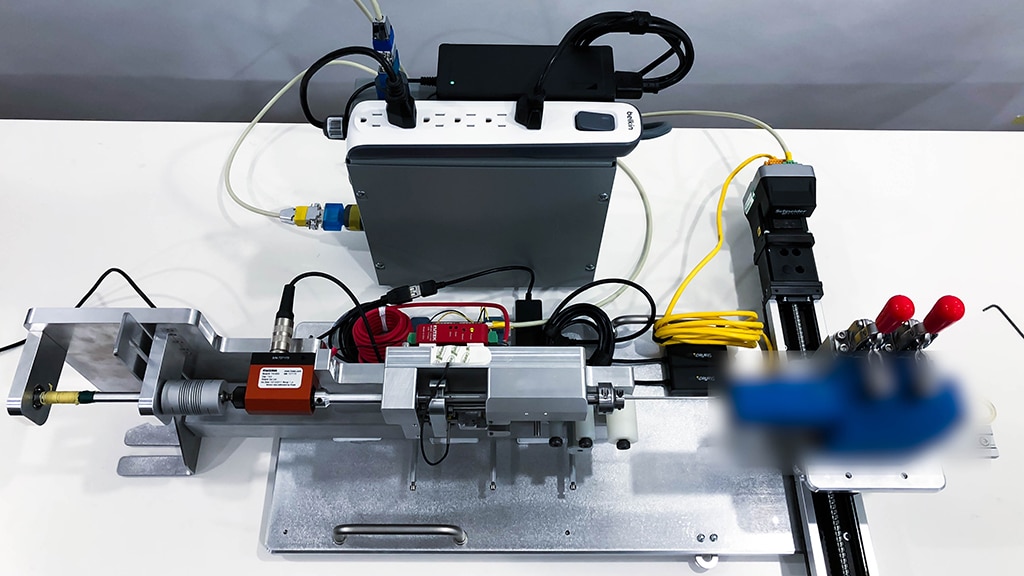

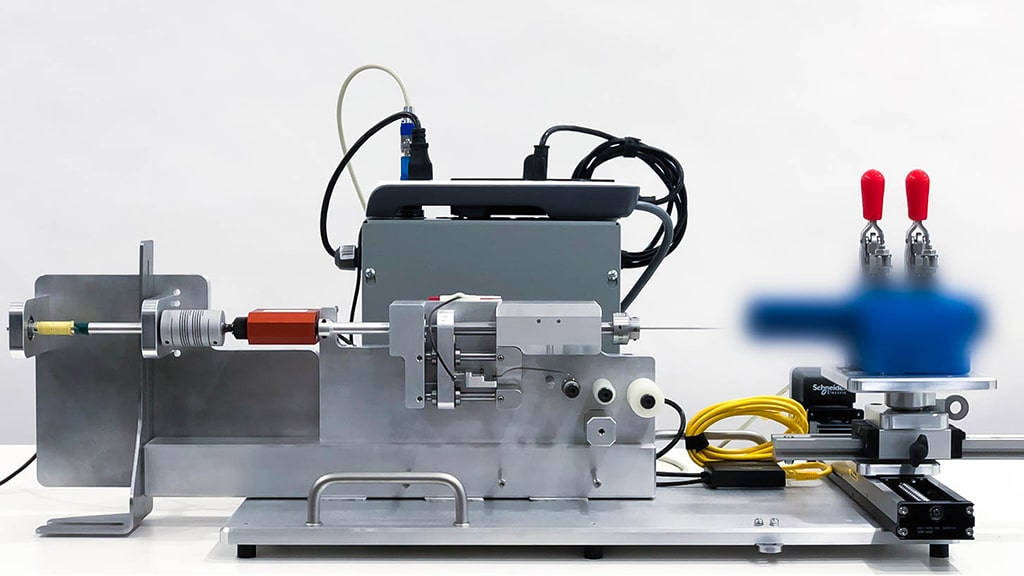

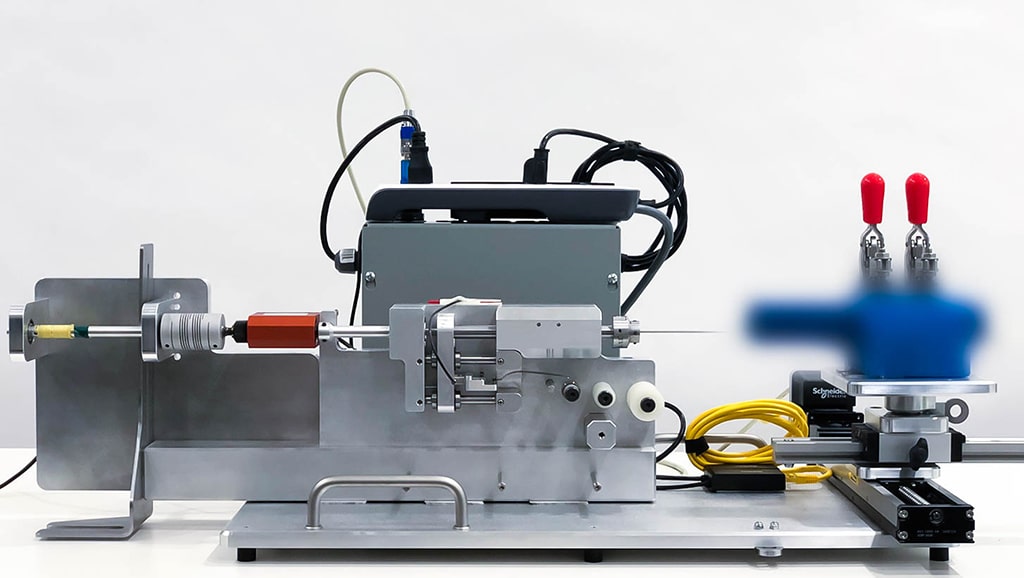

A custom medical device bending fixture that allowed our customer to characterize simulated bending, axial, and torsional load profiles to their device, all while measuring forces in real time. A custom LabVIEW program was also developed by Pipeline to control the automation of the machine.

TEAM:

Mechanical Engineers, Software/Control System Engineer, Electronics/Cabling Engineer, Machinist, Assembly technician

DESIGN TOOLS:

SolidWorks 3D CAD, LabVIEW

MARKET:

Test Fixture, Automation & Motion Control

PROJECT REQUIREMENTS

- Allow bending loads to be applied to device

- Allow axial loads to be applied to device

- Allow torsional loads to be applied to device

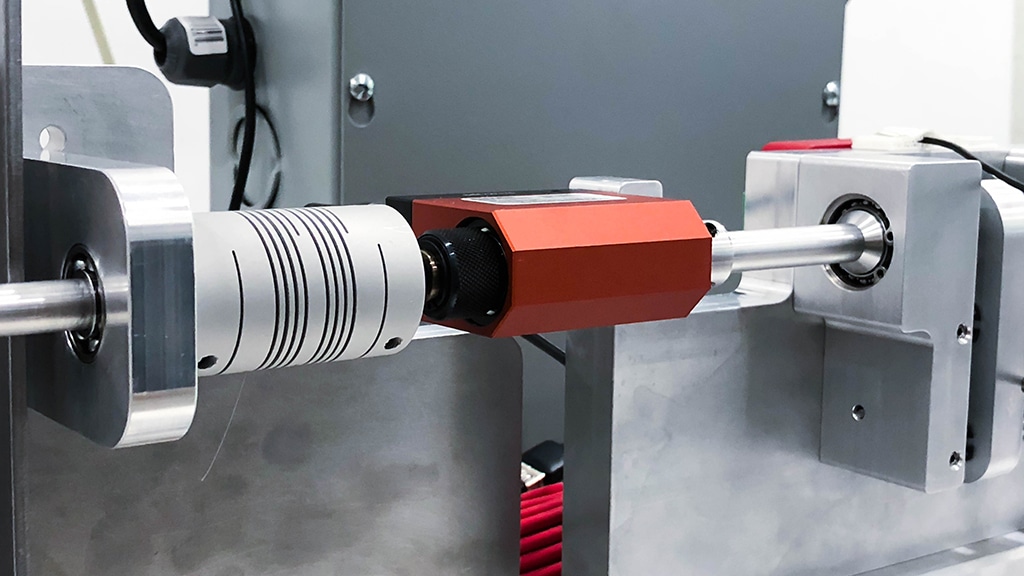

- Measure axial and torsional loads in real time

- Adjust critical parameters via custom software interface

- Modular to accept multiple devices

SUMMARY OF ACTIVITIES

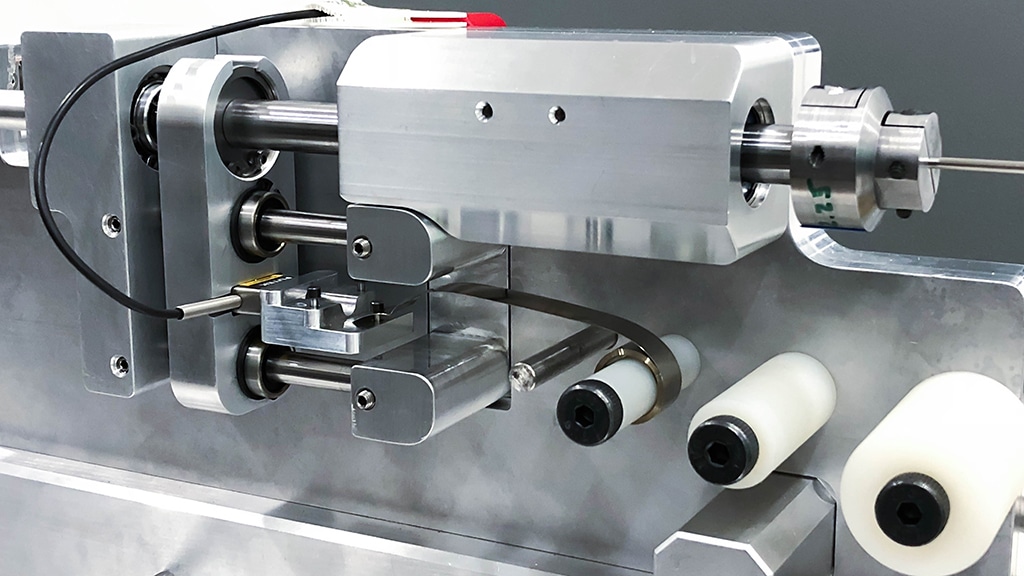

A medical device manufacturer requested Pipeline develop for them an automated bending fixture machine to characterize failure modes of their device. The machine needed to hold a variety of different devices, and allow the operator to apply a range of torsional, axial, and bending load values to the device. To further complicate the process, these loads needed to be applied both simultaneously or individually, depending on the chosen test parameters, and needed to accommodate a rotating member of the device that reciprocated axially. Finally, the resultant torsional and axial loads needed to be measured and displayed on a computer interface.

Pipeline developed a novel mechanical bending fixture that accommodated the axial reciprocation while at the same time applying and measuring axial and torsional output forces from the device. The bending load was implemented as a separate module, but also allowed for simultaneous load application (and a modular solution to accept multiple devices). A custom LabVIEW program was developed to control a motor that drove the bending module. This software application also displayed the load and torque in real time on the computer monitor. Pipeline delivered the system as a fully functional turnkey system to the customer, who was able to immediately begin using it.

Do you need to characterize failure modes in your device? We can help you with custom test fixture design and automation. Contact us today.