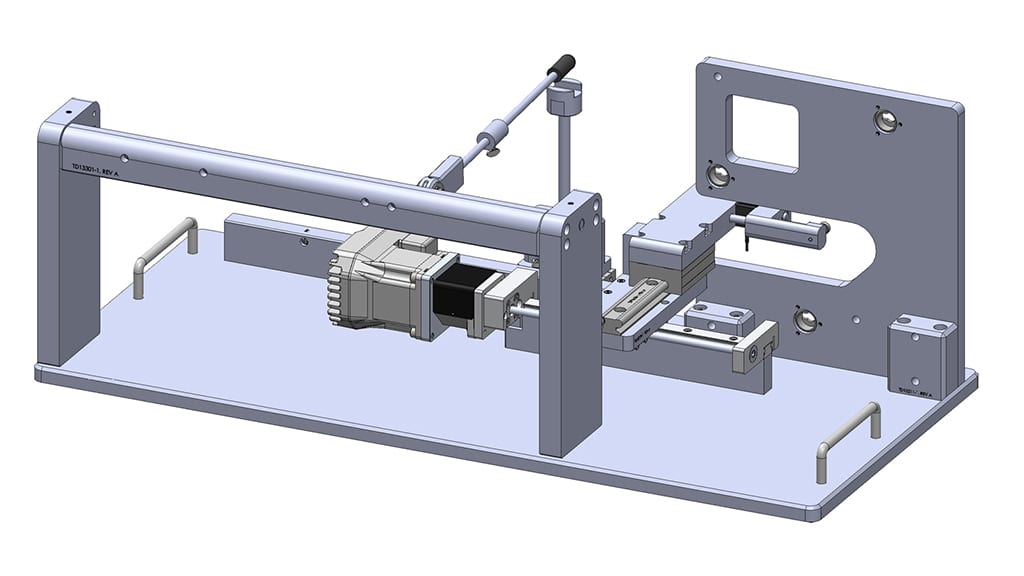

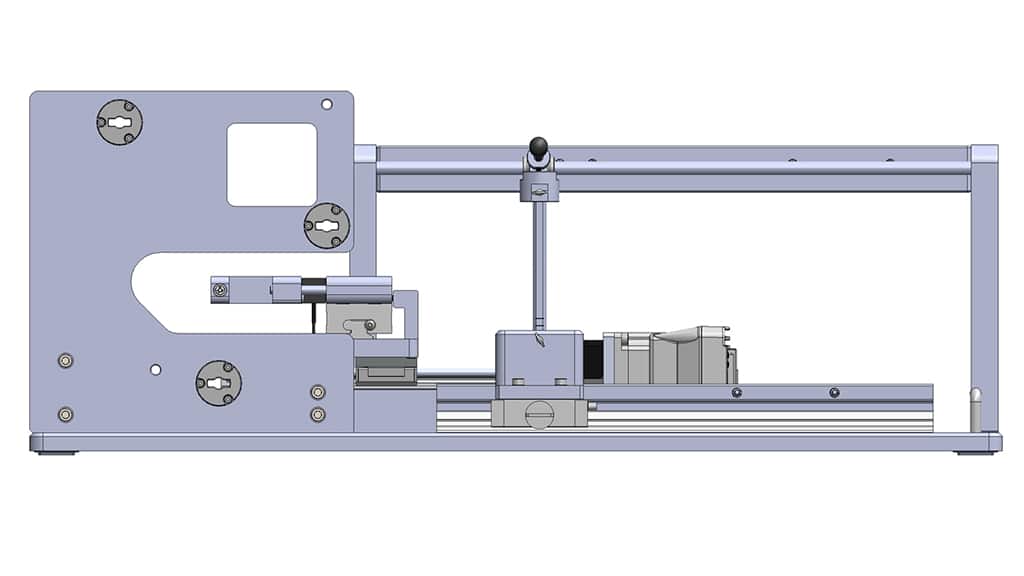

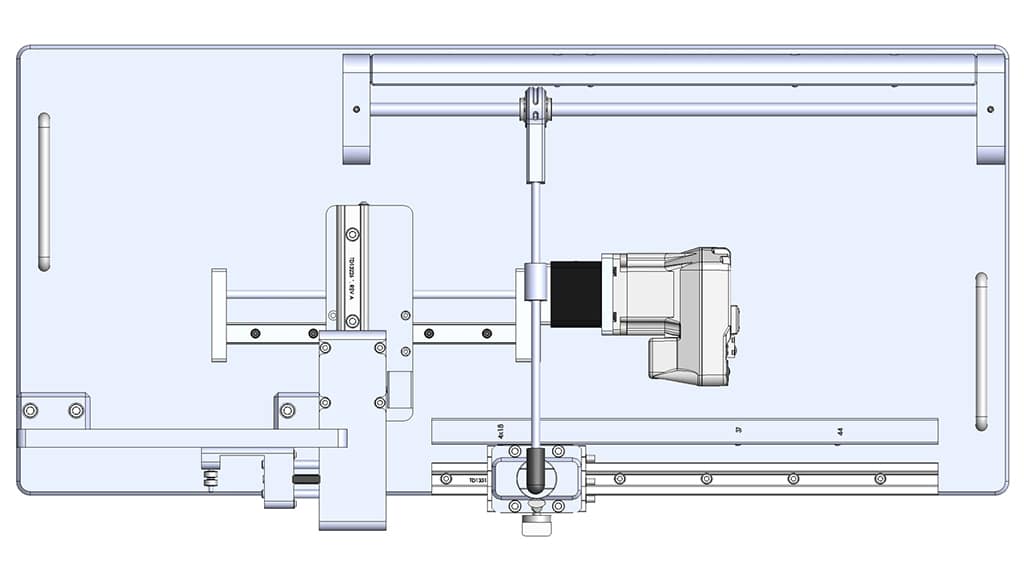

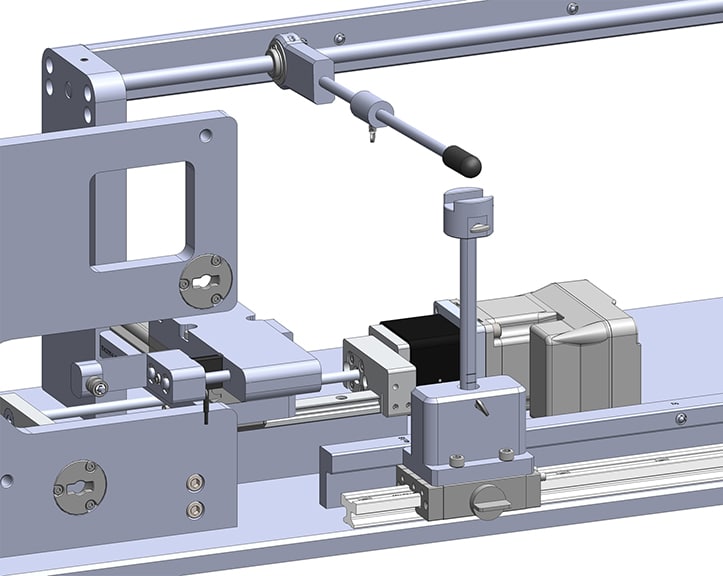

ACTUATION FORCE FIXTURE

PROJECT SUMMARY

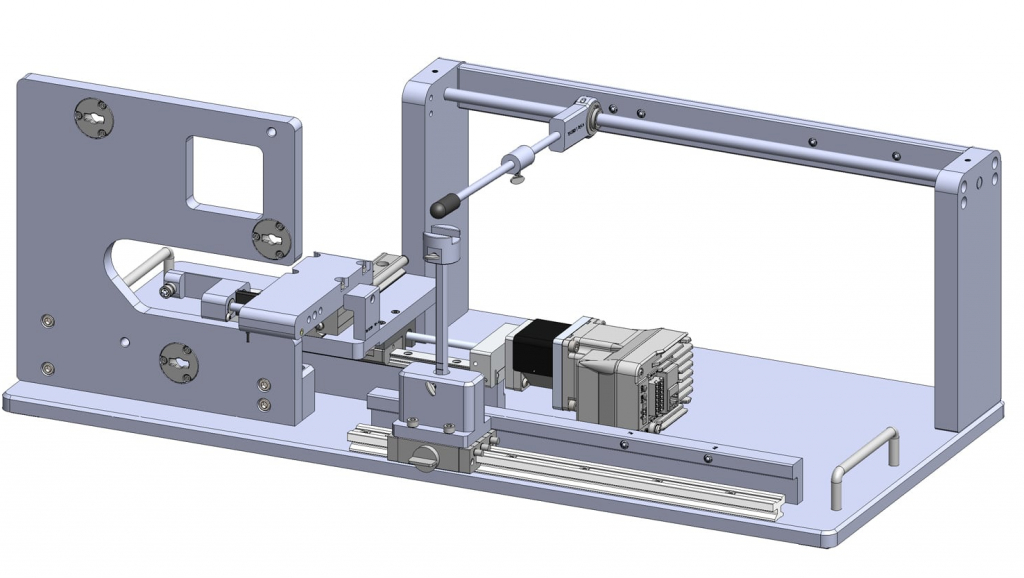

Pipeline Design & Engineering created a modular actuation force fixture that would accept multiple surgical devices and measure the force required to open jaws following operation of the device.

TEAM:

Mechanical Engineers, Software/Control System Engineer, Machinist, Assembly technician

DESIGN TOOLS:

SolidWorks 3D CAD

LabVIEW

MARKET:

Test Fixture, Automation & Motion Control

PROJECT REQUIREMENTS

- Accept multiple surgical devices (from different device families)

- Provide means of tool-free quick release to swap different devices in and out of the fixture

- Simulate surgical procedural steps in a controlled manner

- Automate the actuation of a lever of each device

- Automate the measuring of the force required to open device’s jaws

SUMMARY OF ACTIVITIES

A medical device manufacturer approached Pipeline about building a machine that would allow them to measure the force required to actuate a mechanism on their device in a repeatable manner (i.e. an actuation force fixture). The mechanism required very little force to actuate and thus was extremely sensitive to actuation force. Furthermore, the fixture needed to accommodate three unique devices each with its own set of features & geometry. Finally, the customer requested that the actuation be motorized and controlled via a custom software interface.

Pipeline developed modular holder elements (one for each unique device) that could be quickly and easily swapped in and out of the main fixture. A high-precision/low force value in-line load cell was selected from Futek and integrated into a nearly frictionless custom carriage. This carriage interfaced with the devices’ handles and actuated the handle mechanism. A Lexium MDrive motor was integrated into a lead screw linear actuator to automate the motion of the carriage/load cell. Finally, a custom LabVIEW program was written to facilitate the motion profile of the actuation force fixture. The finished assembly was delivered to the customer as a turnkey solution.

What forces do you need to measure for design verification? How could support with test fixture design advance your project? Contact us today to learn more.