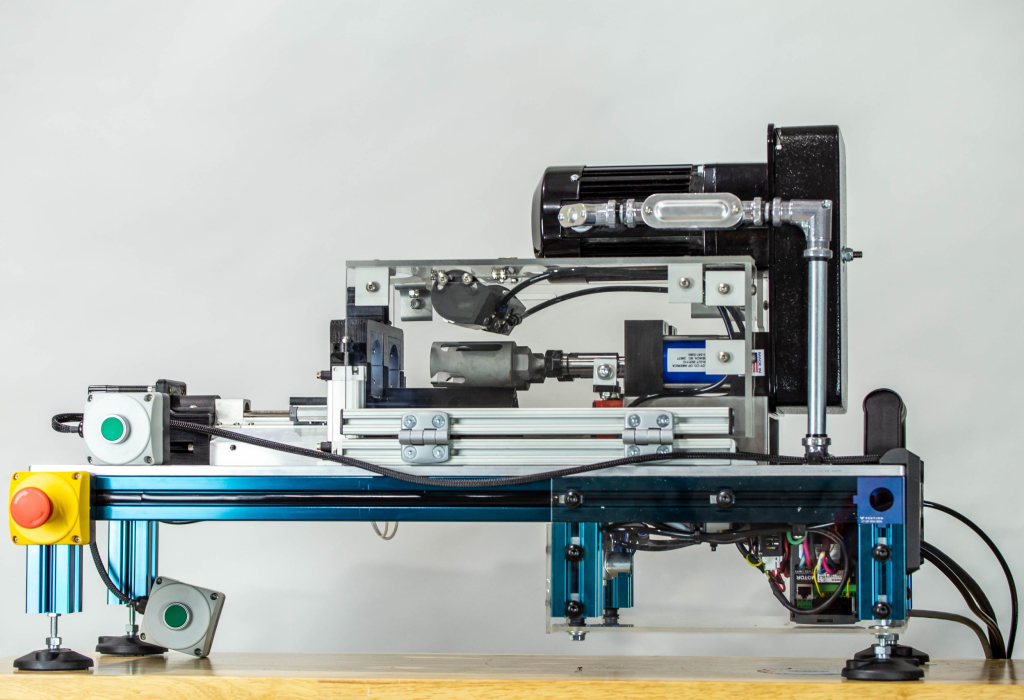

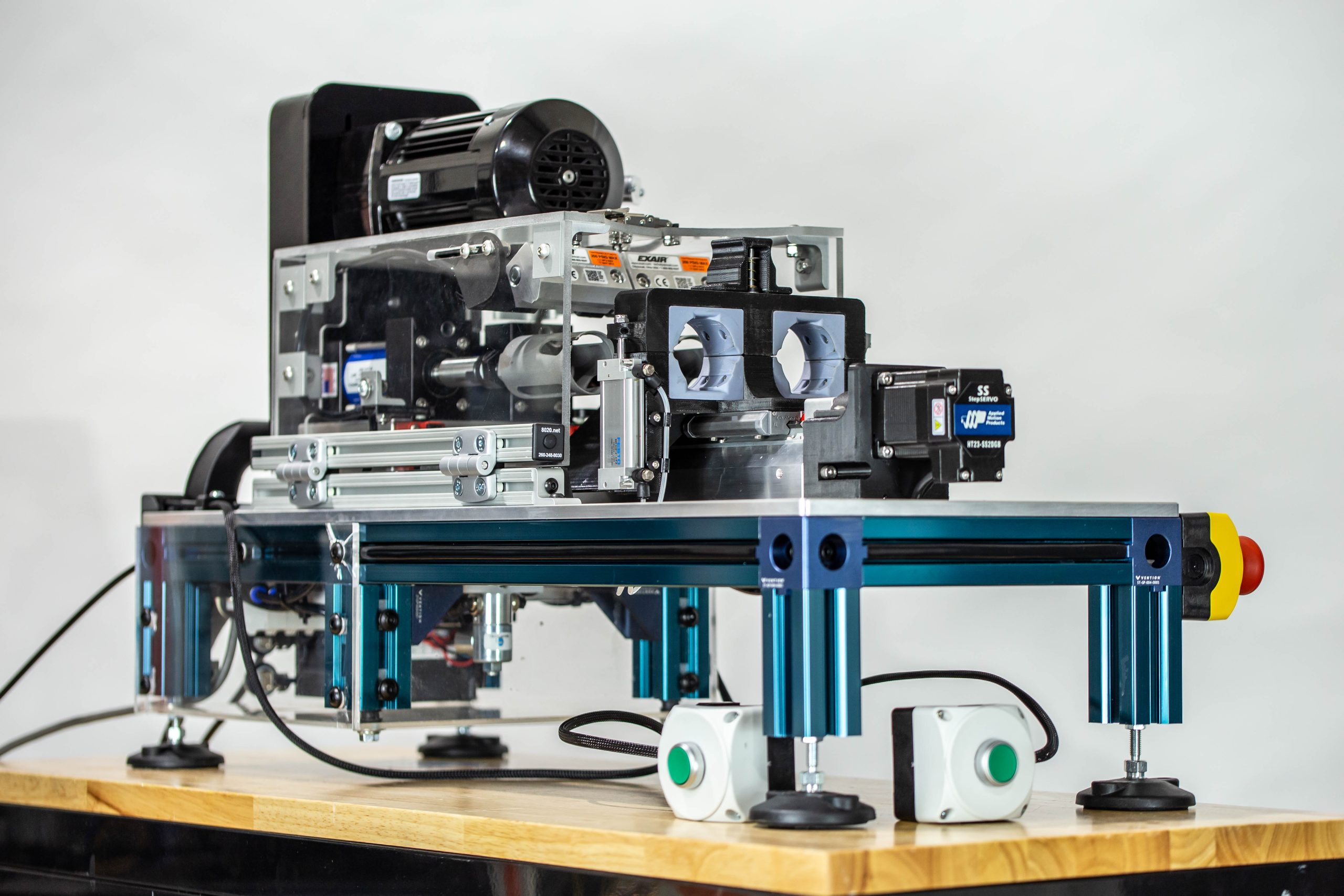

DRILL FIXTURE

DRILL FIXTURE SUMMARY

Pipeline developed an automated 2-up drill fixture to remove a precise amount of material from a medical device as part of an in-line processing step in the manufacturing. .

TEAM:

Mechanical Engineer, Controls Engineer, PLC Programmer

DESIGN TOOLS USED:

Solidworks, 3D Printing

MARKET:

Medical Devices

PROJECT REQUIREMENTS

- Remove a precise amount of material from a medical device, in a precise location

- Process two devices at a time (2-up)

- Include safety features to protect the operators

- Minimize cycle times

SUMMARY OF ACTIVITIES

Custom (circular) drill bits were manufactured to facilitate the precision material removal required for the drilling fixture. These drill bits were connected to an industrial motor to ensure long life and reliable performance during production, and mounted to a custom-made frame. A rail and carriage setup was used to move the device components in and out of the drilling zone, and safety enclosures were used to shroud this zone to protect operators.

The drilling fixture machine was controlled using an industrial PLC (programmable logic controller) which Pipeline programmed with the necessary steps to turn the drill heads on and off, and move the component nests in and out of the operational zone. Once the drill operation was completed, the nest automatically opened so the operator could easily remove the processed components.

The end result of using the drilling fixture was that an operation which had been cumbersome to perform manually in the past by operators can now be performed precisely and repeatably each time via the automation and precision features built into the machine. To learn more about how your team can leverage our team for custom test fixture design, contact us today.