MEDICAL DEVICE NAVIGATION FIXTURE

MEDICAL DEVICE NAVIGATION FIXTURE SUMMARY

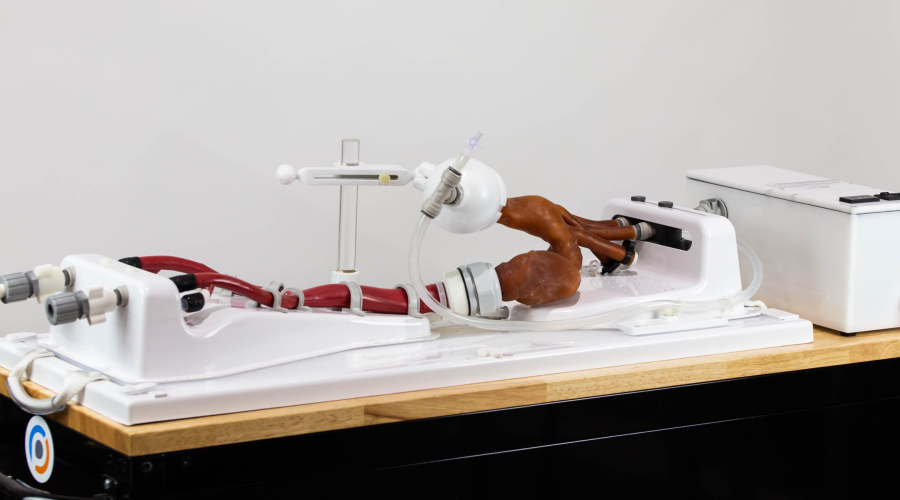

The customer needed a way to test the surgical navigation of a new medical device through simulated vasculature, including fluid flow at body temperature.

TEAM:

Mechanical Engineer, Controls Engineer

DESIGN TOOLS USED:

Solidworks, 3D Printing

MARKET:

Medical

PROJECT REQUIREMENTS

- The surgical navigation fixture needed to accommodate a wide range of different vasculature geometries to represent different patients

- Include a closed loop system for circulating fluid at body temperature (to simulate blood flow)

- Set up within clinical environment within 5 minutes

- Easy to clean

SUMMARY OF ACTIVITIES

The customer had an existing prototype of their surgical navigation fixture that had been used for engineering studies, but was cumbersome to use in a clinical environment and took too long to set up (45 min+). Pipeline redesigned the fixture, including many unique and innovative improvements, as well as incorporate a more pleasing aesthetic reflective of the clinical environments in which it would be used.

3D printing was used heavily to rapidly evaluate various design options for the surgical navigation fixture. The main components of the fixture were ultimately produced via thermoforming. The entire fixture was made leak proof using a variety of tubes and seals that created the closed loop flow, facilitating a realistic representation for surgeons to practice their device navigation on patient-specific vasculature & anatomy prior to the actual surgery. A variety of adjustments were incorporated so the fixture would accommodate the various anatomies and vasculatures. A novel process for creating patient-specific vasculature was also developed as part of the project.

For more examples of how your team can leverage ours on test fixture design, view our case studies or contact us.