GELLIFLEX ABACUS

PROJECT SUMMARY

Pipeline Design & Engineering worked closely with the inventor to design a novel massage device. The innovative features allow users to adjust settings to fit their specific anatomy.

TEAM:

Mechanical Engineer

Industrial Designer

Manufacturing Vendor

DESIGN TOOLS:

SolidWorks 3D CAD

Photorealistic Rendering

FEA

MARKET:

Consumer Product

PROJECT REQUIREMENTS

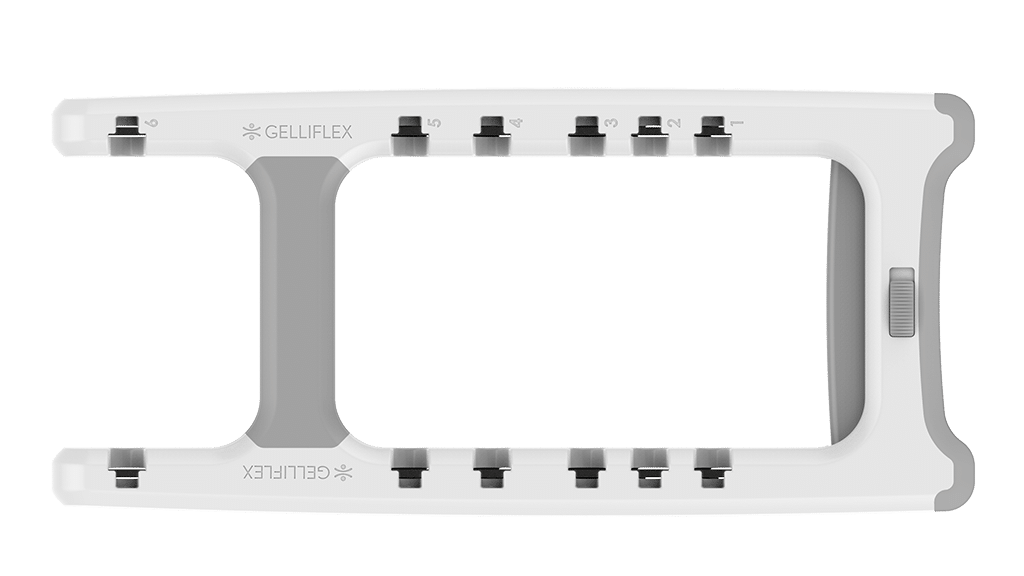

- Quickly and easily allow user to adjust spacing to fit unique anatomy

- Develop feature to passively hold ball assemblies in place, while at the same time allowing users to remove ball assemblies when desired

- Locking mechanism to prevent ball assemblies from being removed unintentionally

- Aesthetic styling and comfortable materials

- Design for mass production (injection molding)

- Withstand high forces during use

SUMMARY OF ACTIVITIES

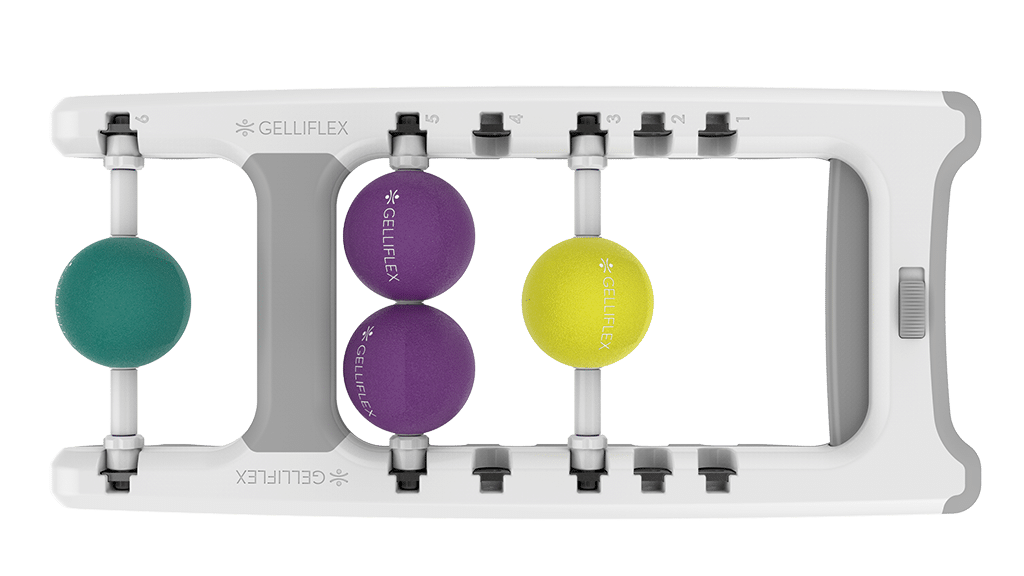

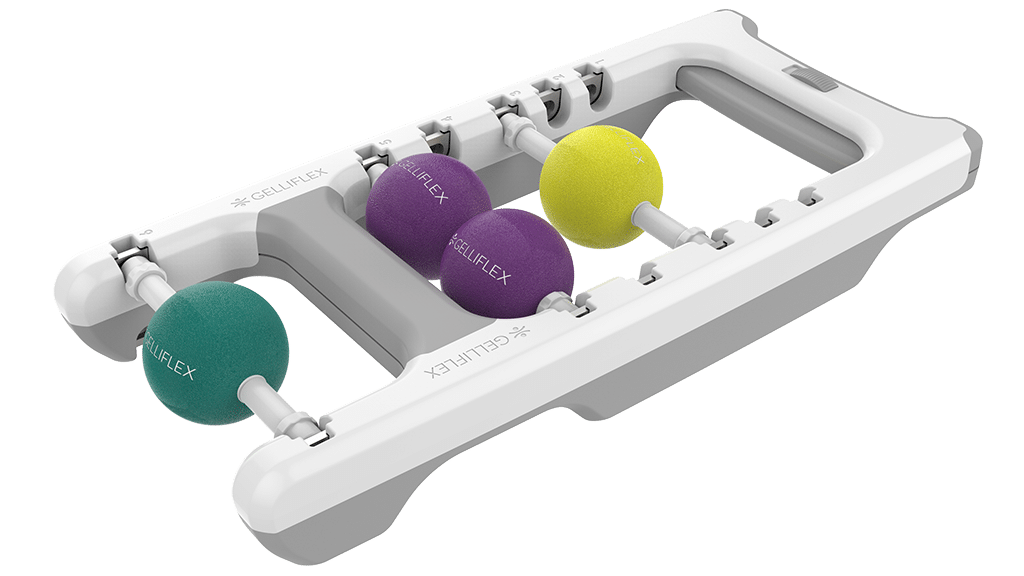

The Gelliflex Abacus was created for individuals who suffer from repetitive stress injuries, such as computer programmers, massage therapists, gamers, and golfers. The innovative compliant massage balls roll freely around an axle, allowing for smooth massage motions that contour to a user’s individual anatomy. The modular design of the frame also allows users to space ball assemblies as close or far apart as is needed to achieve the desired therapeutic effect.

Thoughtful design elements were added to maximize ease of use for users, such as a braille & standard numbering scheme to identify ball assembly positions, spring-loaded retention system, and an innovative passive axle holding feature that leveraged the intrinsic capabilities of the injection molding manufacturing process.