3D SCANNING AND CONVERSION OF AEROSPACE SEAT TRAY

PROJECT SUMMARY

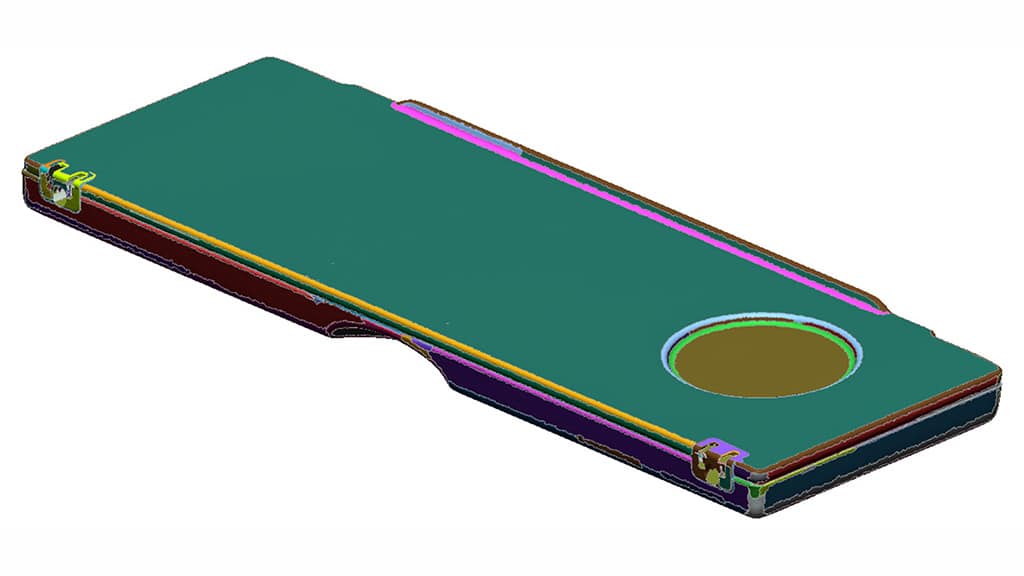

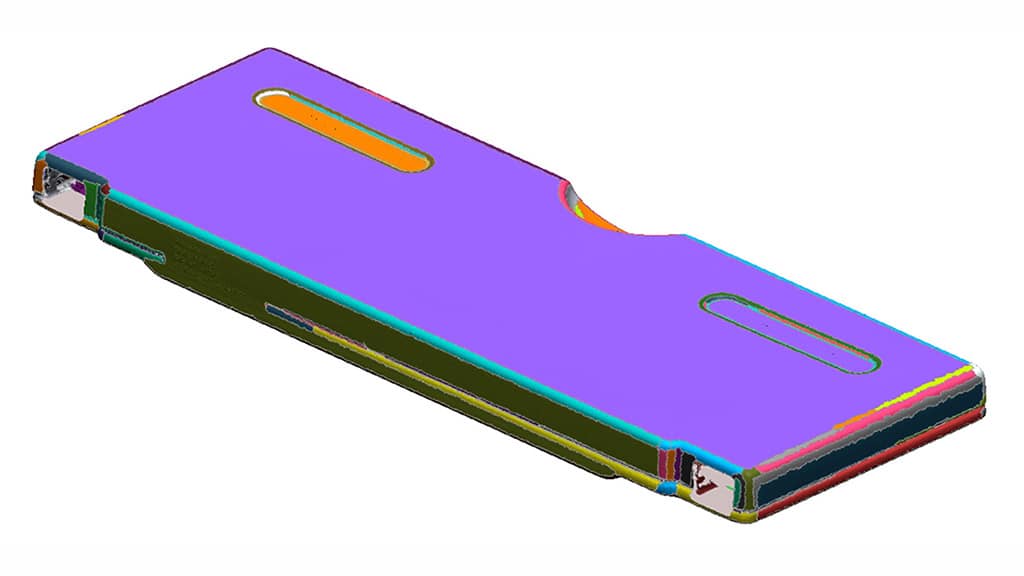

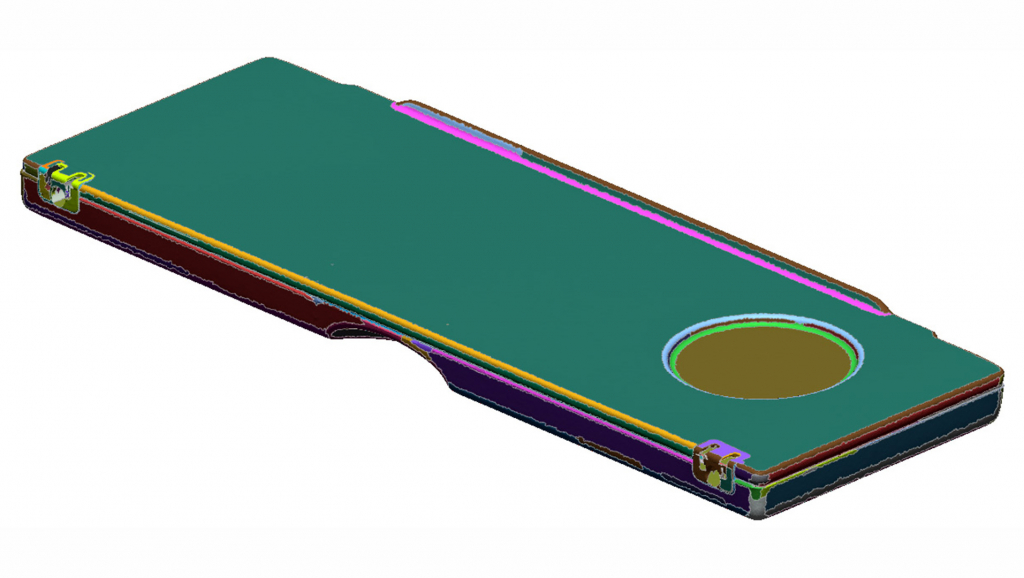

The customer maintains a product line of patented designs and was hired by the airline to integrate one of their products into a tray table. This customer did not have access to the original design files. With the use of 3D scanning, Pipeline digitized the customer’s part and then modified it to accept an off-the-shelf cell phone holder.

TEAM:

Mechanical Engineer

Specialized Manufacturer of Tray Tables

DESIGN TOOLS USED:

SolidWorks 3D CAD

Geomagic DesignX 3D Scan Processing

Photorealistic Rendering

High Resolution 3D Scanner

MARKET:

Commercial Product

PROJECT REQUIREMENTS

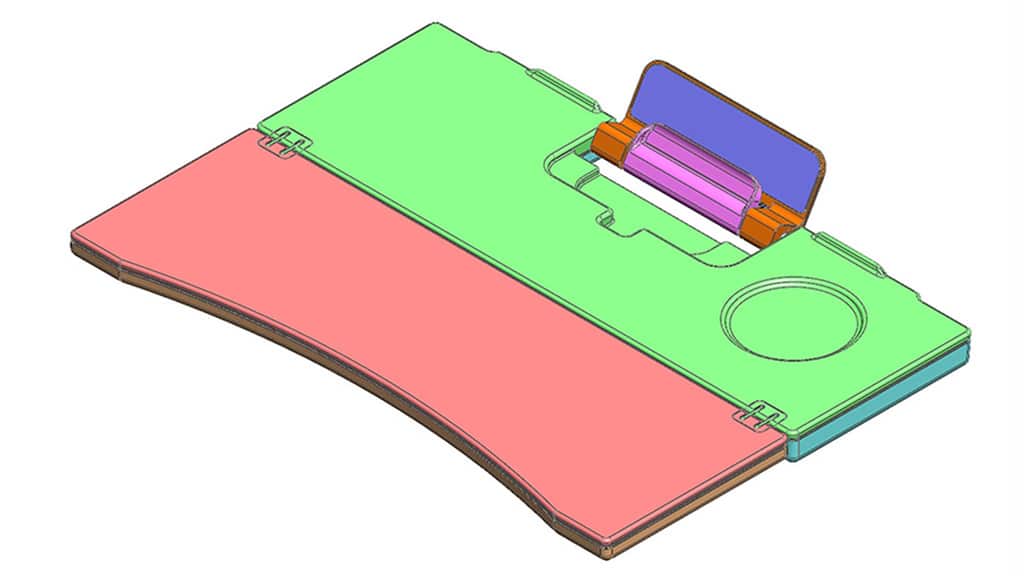

- Update the OEM tray design to accommodate Smart Tray International’s proprietary device holder.

- Maintain majority of OEM tray geometry (any substantial functional changes would require expensive re-certification and testing of the tray)

- Produce complete set of manufacturing documentation so the tray could be produced via production processes

SUMMARY OF ACTIVITIES

The physical OEM tray components were scanned in house using Pipeline’s 3D scanner, and then converted into 3D parametric CAD components in house using specialized scanning software. An assembly was created in CAD, and new assembly was then modified to accommodate the Smart Tray device holder.

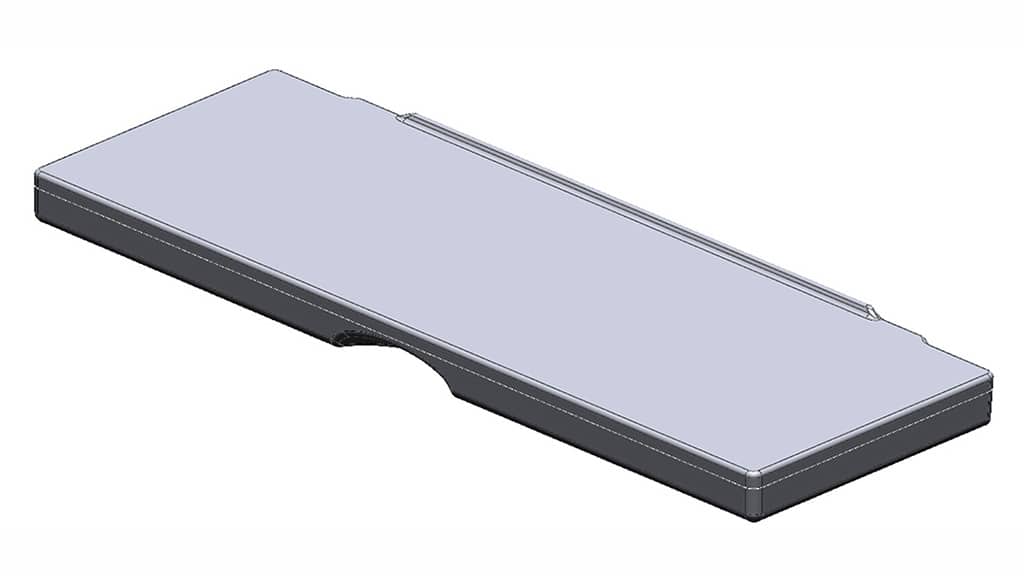

Once the integration was complete, manufacturing drawings were produced and approved by the customer and all files were transferred to their file share. While the parts were being manufactured, a photorealistic rendering was made of the final product for marketing purposes.