Endoscope Camera Image Quality Fixture

ENDOSCOPE CAMERA IMAGE QUALITY FIXTURE SUMMARY

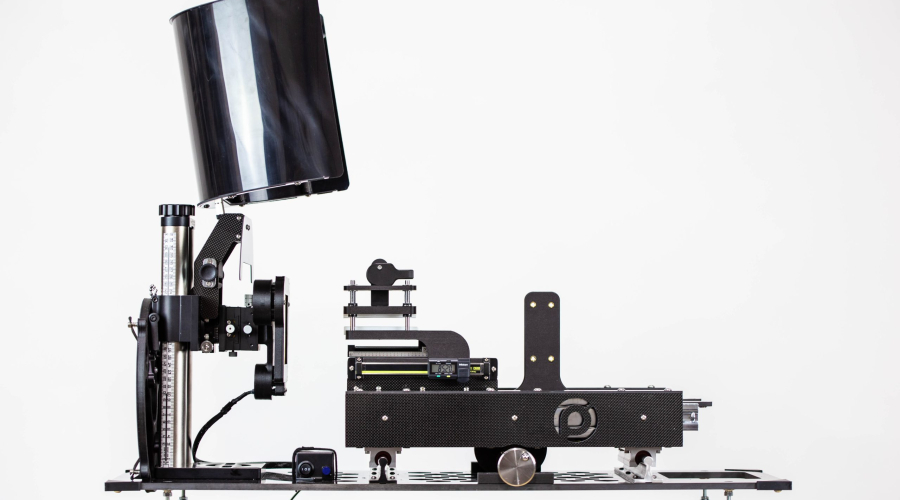

Pipeline designed and built a fixture to test or verify the resolution and image alignment of any endoscopic or laparoscopic camera.

TEAM:

- Mechanical engineer

- Controls engineer

- Software engineer

- Technician

DESIGN TOOLS USED:

- Solidworks

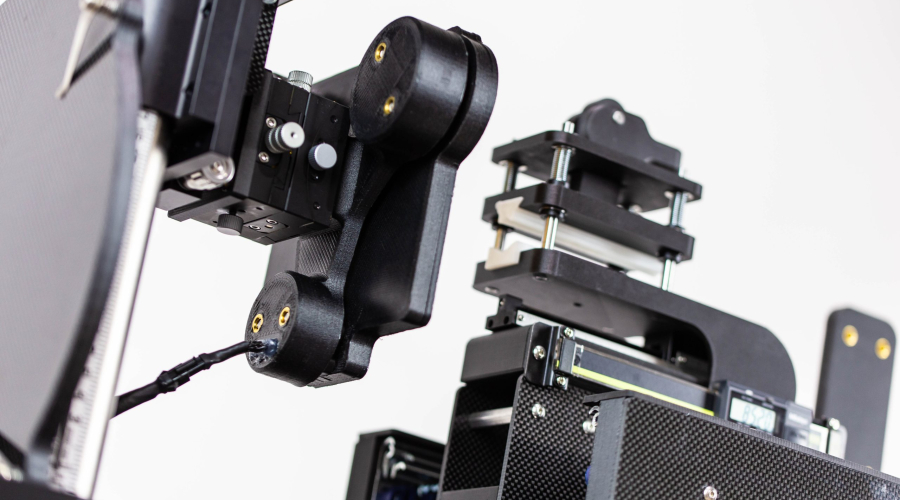

- 3D Printing

- LabVIEW

MARKET:

Medical device test equipment

PROJECT REQUIREMENTS

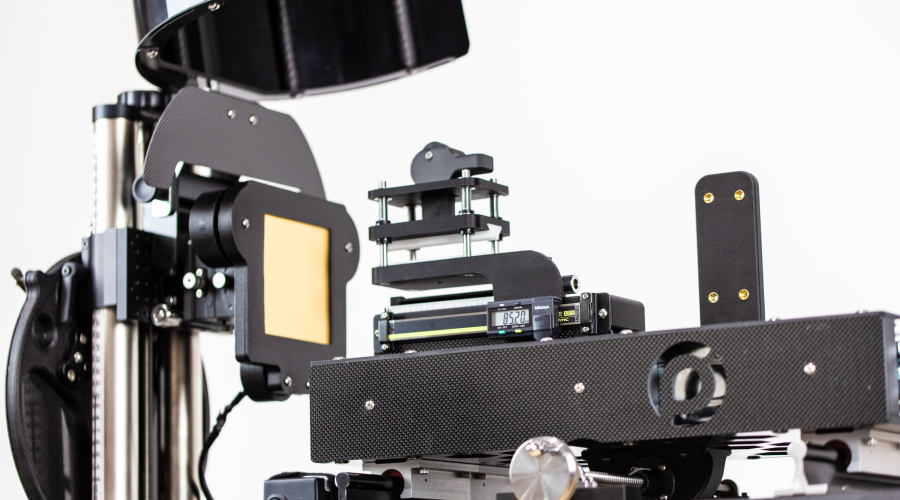

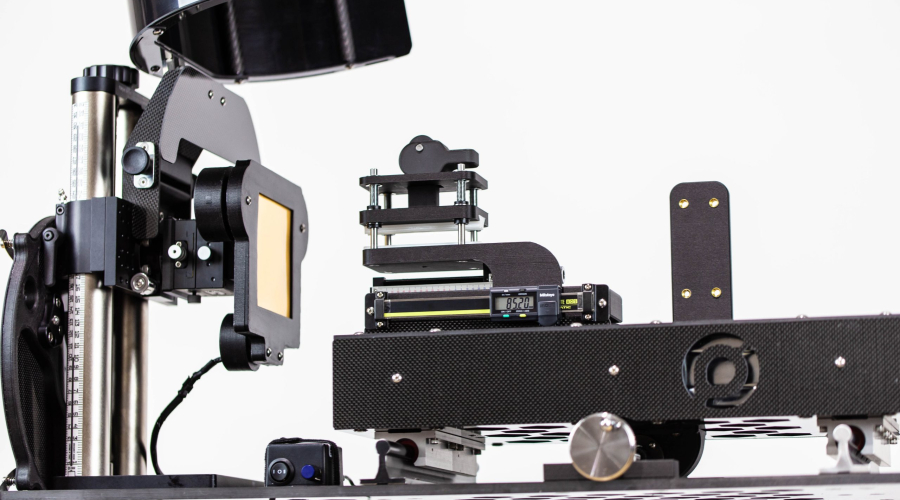

- Three axis micrometer adjustment with digital readout

- Uses either a projection screen or a printed target as the test image

- Yaw, pitch and roll can be adjusted on the target or test screen

- Interchangeable device nests to allow testing for a wide variety of endoscopic or laparoscopic cameras

- Flexible hood to fully block ambient light allowing testing of camera on-board lights

SUMMARY OF ACTIVITIES

Pipeline’s customer produces a variety of devices using endoscopic or laparoscopic cameras and needed a way to test the cameras early in the assembly process and also as a final quality check prior to packaging. The fixture needed to be able to quickly accommodate a wide range of devices, so the Pipeline team developed a tabletop fixture with XYZ linear rails that allow for a quick rough set-up. The final precise positioning of the camera in each axis was accomplished using micrometer adjustments with digital readouts. Each axis also had analog distance indicators so that the rough position of a device type could be recorded and quickly recreated when needed.

Due to the different natures of the devices, some cameras needed to be tested using a backlit computer-generated test target and some required more traditional tests such as the NBS 1952 Resolution Test, the 1951 USAF Target or the High-Frequency NBS 1963A Target. The target platform needed to be able to pitch, roll or yaw up to +/-45 degrees from perpendicular to the camera axis.

A LabVIEW program was written to assist with capturing and categorizing the resultant camera images and storing them in a database for archival reference.

Learn about other ways your team can leverage ours to develop custom equipment, fixtures, and automation.