TUBE STRAIGHTENING FIXTURE

TUBE STRAIGHTENING FIXTURE SUMMARY

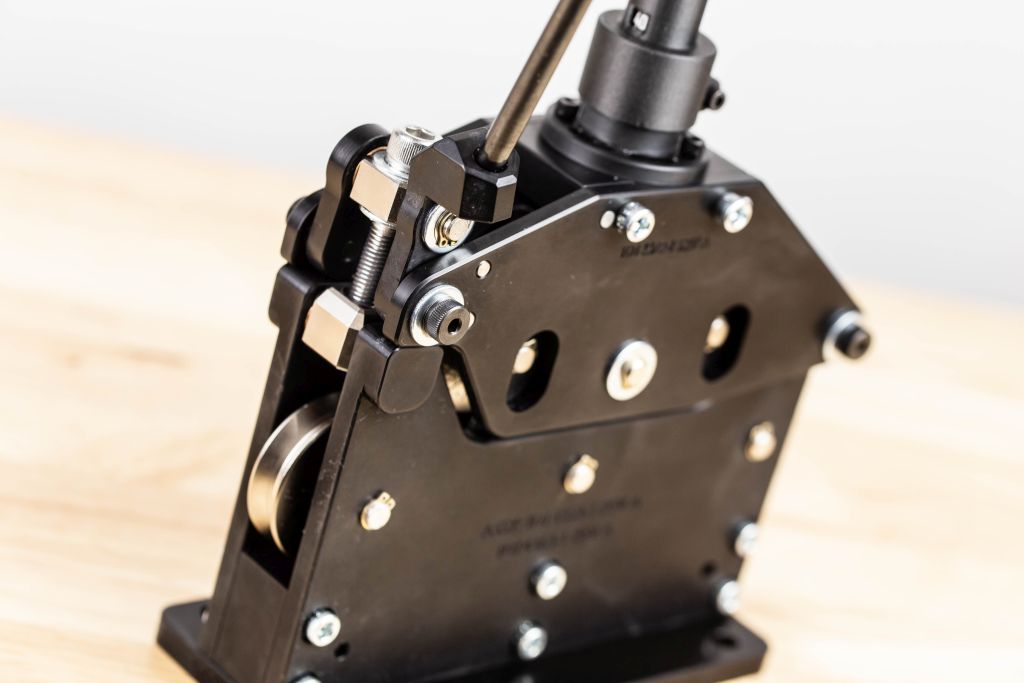

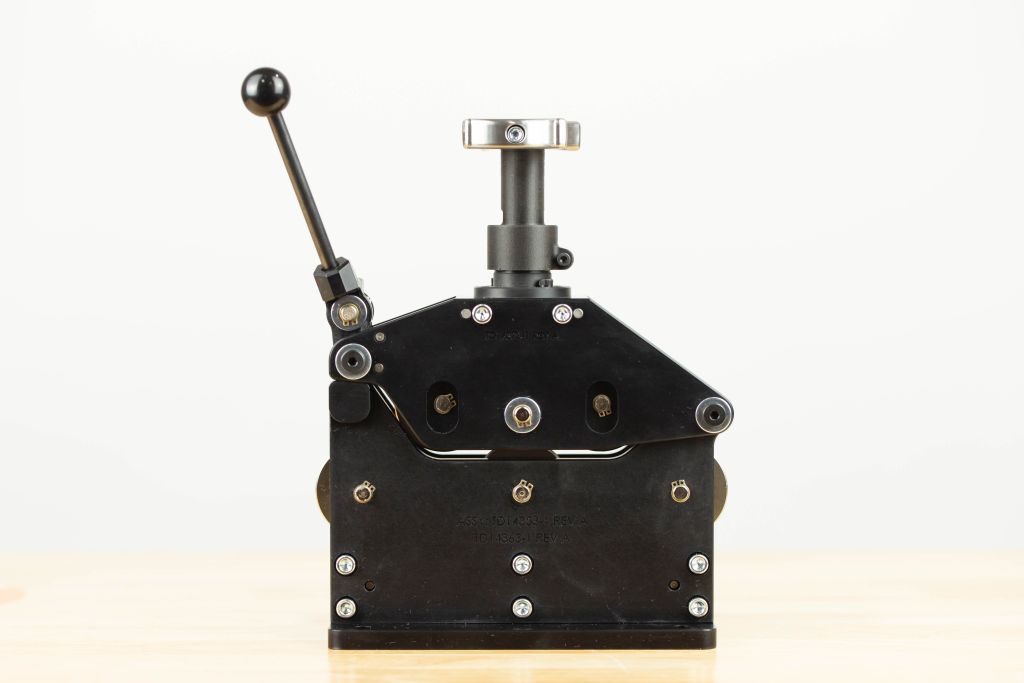

Pipeline developed and manufactured a tube straightening fixture for medical device reprocessing, accommodating a range of shaft sizes for straightening multiple device types.

TEAM:

Mechanical Engineer

DESIGN TOOLS USED:

Solidworks

MARKET:

Medical Device Manufacturing and R&D

PROJECT REQUIREMENTS

- Quick tool-less method of opening the tube straightening fixture for device shaft insertion and removal

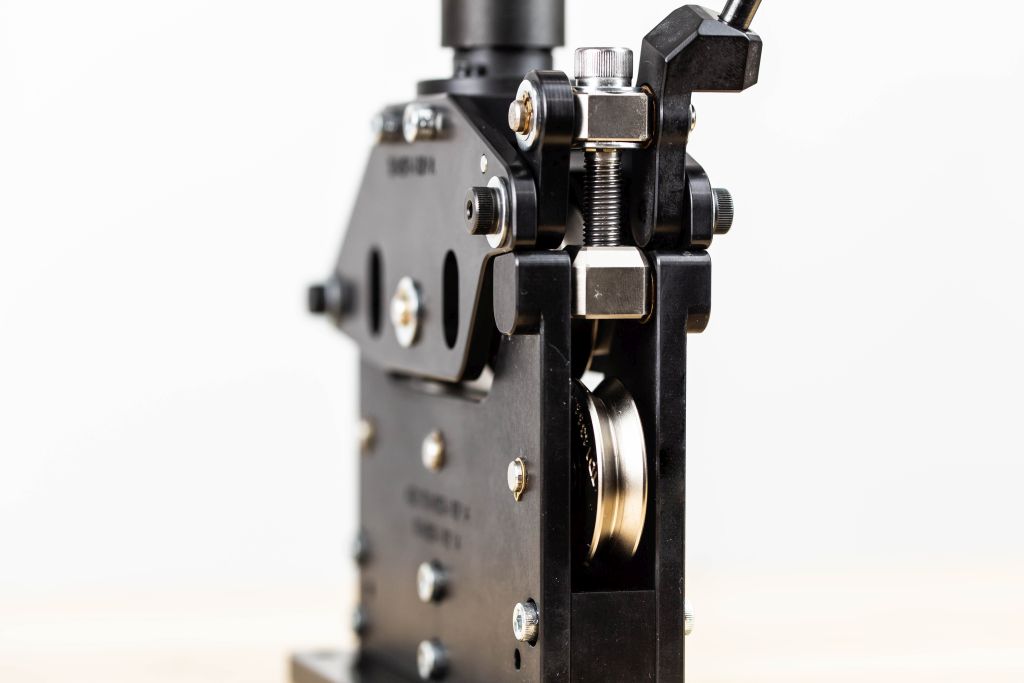

- Adjustable and repeatable compression of shaft tube during straightening procedure

- Can accommodate a range of shaft tube outside diameters

- Smooth, easy turning of wheels during manual straightening of shafts to minimize force required

SUMMARY OF ACTIVITIES

Our customer desired an improved method of straightening shafts of devices slated for medical device reprocessing, since many were out of spec (shafts were bent or deformed). There are existing methods of tube straightening but not as repeatable as desired, and none that would accommodate the specific geometry of our customer’s shafts.

Pipeline utilized master modeling to create a user-friendly tube straightening fixture capable of manually straightening various shafts (and could be upgraded with industrial automation if desired). The fixture is calibrated prior to delivery such that the setting markings are consistent between units. With a simple adjustment knob at the top and numbers that correlate to compression amount, the fixture can be adjusted on the fly.

Manufactured from machined aluminum and steel, 3D-printed chopped-carbon nylon, and off-the-shelf components, this tube straightening fixture now assists the customer in preventing or improving reprocessing delays because of out-of-spec device shafts. The fixture is designed to eliminate misuse, as well, and simply requires an operator to run the device’s shaft back and forth through the straightening mechanism several times.