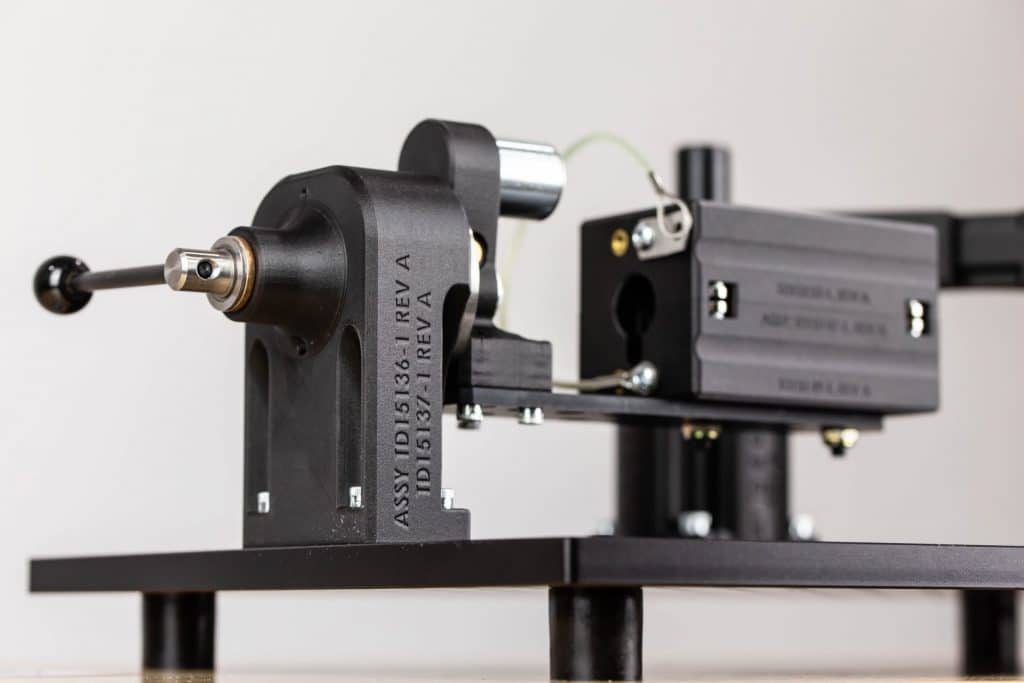

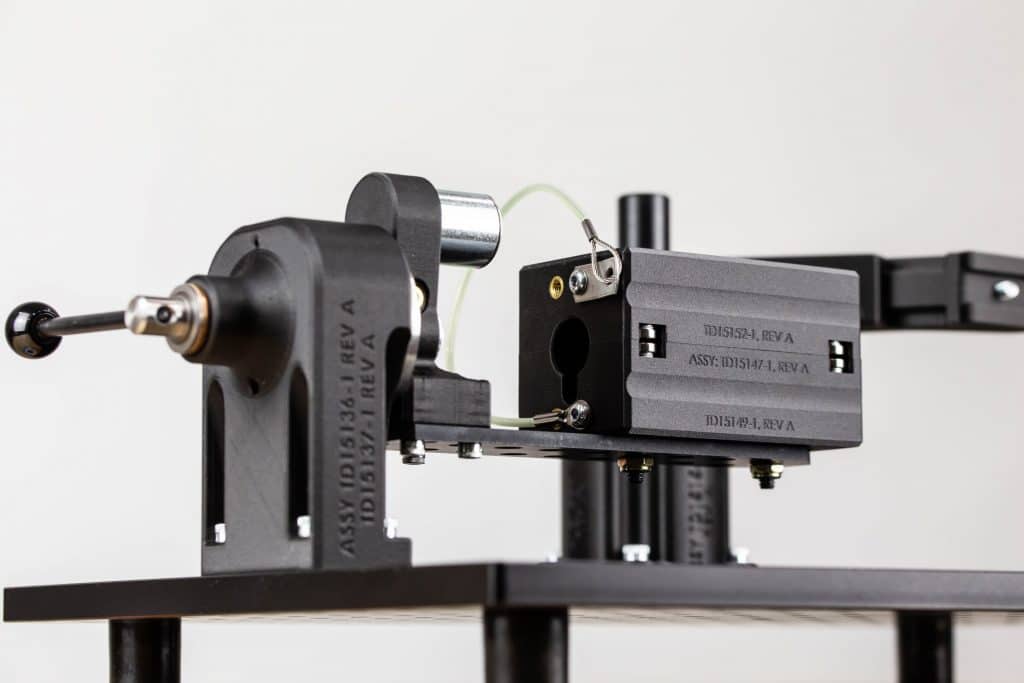

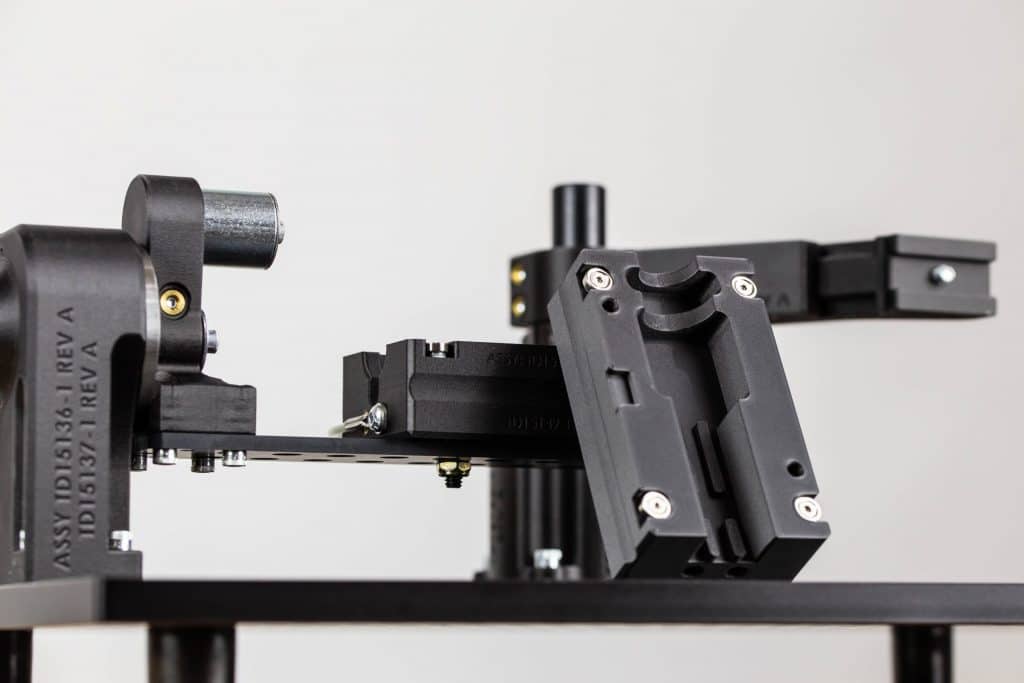

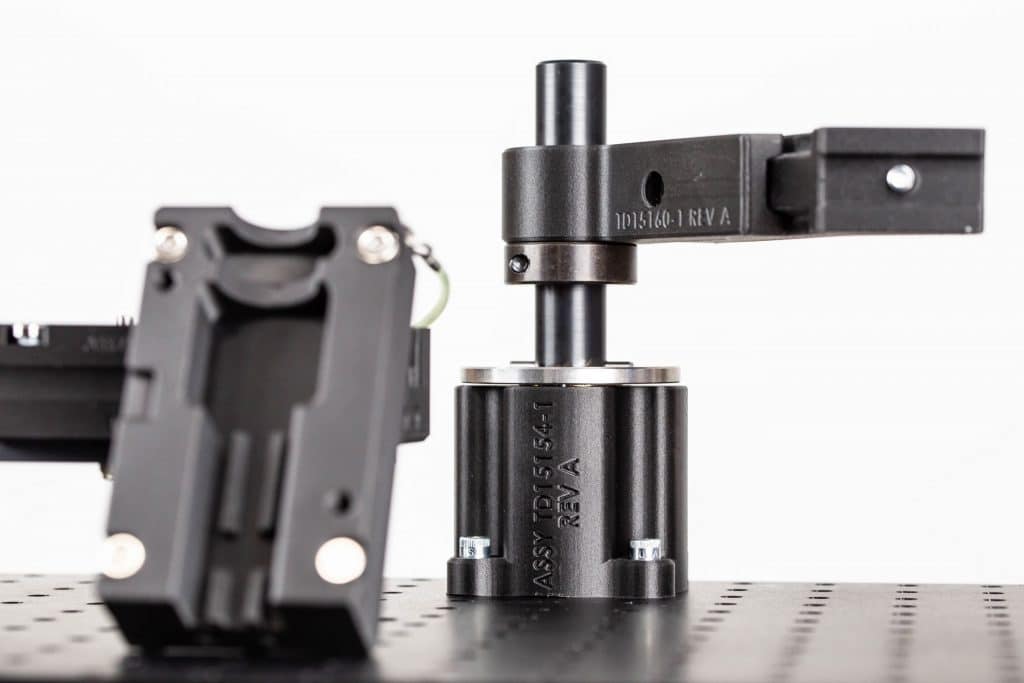

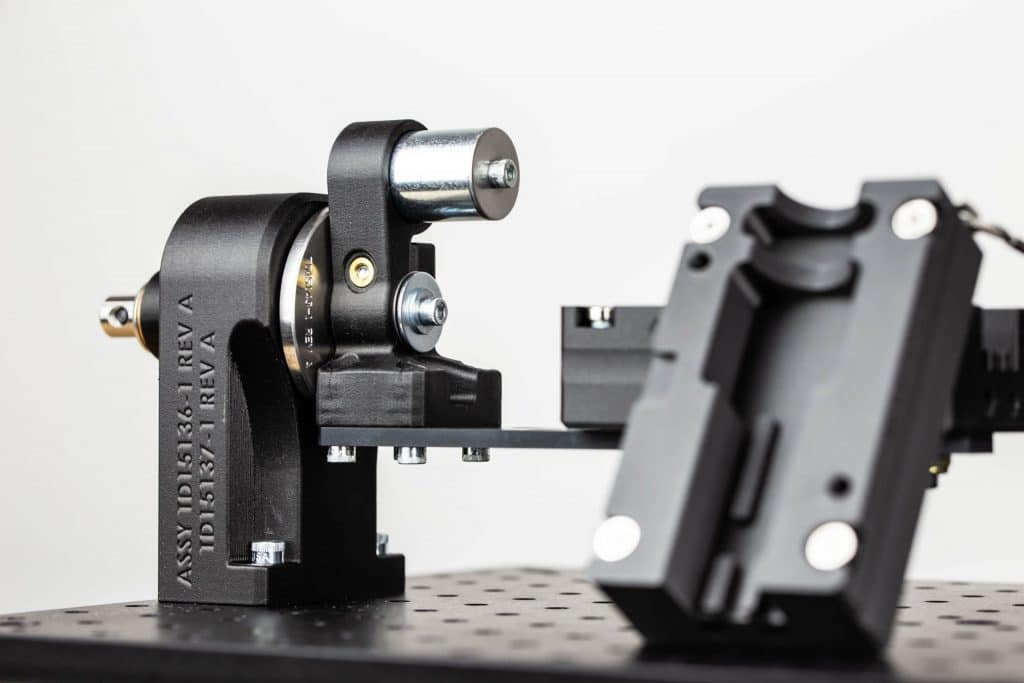

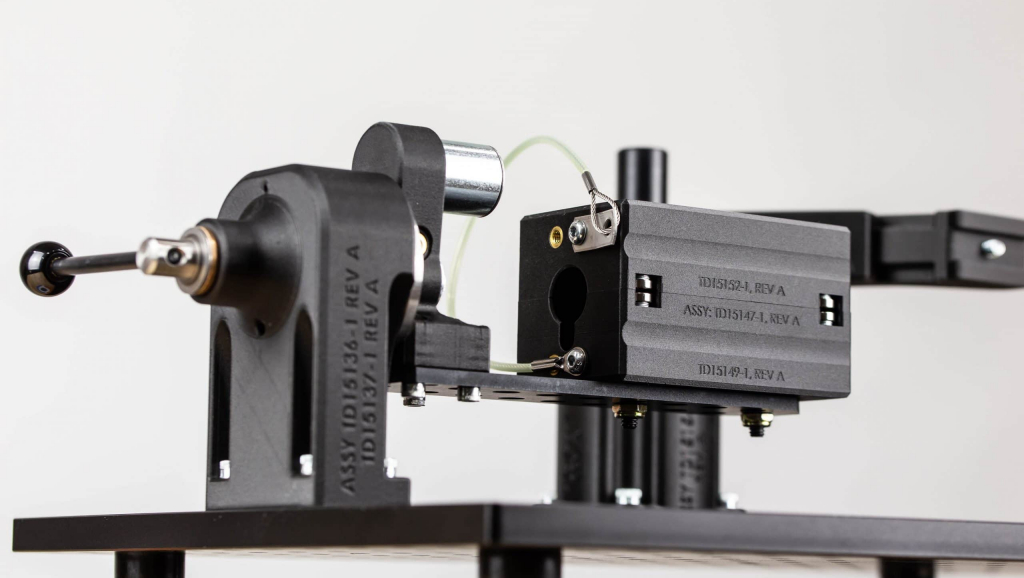

Gluing Fixture

FUNCTIONAL TEST STATION SUMMARY

Pipeline designed and manufactured a standalone gluing fixture to assist the repetitive gluing and curing of parts on a catheter shaft.

TEAM:

Mechanical Engineers

DESIGN TOOLS USED:

Solidworks

MARKET:

Medical Device Manufacturing and R&D

PROJECT REQUIREMENTS

- Securely hold the device with quick, toolless method

- Hold curing lamp 8-12 mm above gluing area

- Allow curing lamp to repeatably be moved out of the way and back to gluing area

- Allow device to repeatably rotate 180° around device central axis and back to 0°

- Build in adjustability for precise positioning of curing lamp

SUMMARY OF ACTIVITIES

The gluing fixture includes a curing lamp positioned precisely above the location on the catheter that receives adhesive, then afterwards the curing lamp can be moved out of the way for inserting/removing the device and adding glue for all units glued. The catheter handle is set in its nest, while the distal end is left free for simplicity. Once the device is in place, the curing lamp is moved into position and the first side cures. Then the device is rotated 180° for the opposite side to be cured as well.

The gluing fixture has swappable plates which can create a multitude of detents and rotation ranges, including even not having a hard stop (allowed to rotate fully). Activities performed during development include preliminary design, internal design review meetings, detailed design, multiple design review meetings with customer team, final design, manufacturing, assembly, internal test and validation, delivery, customer test/validation/measurement systems analysis.

Are you looking for a group who can help your team with test fixture design custom equipment, or automation? Contact us today.