Catheter Tip Deflection Fixture

CATHETER TIP DEFLECTION FIXTURE SUMMARY

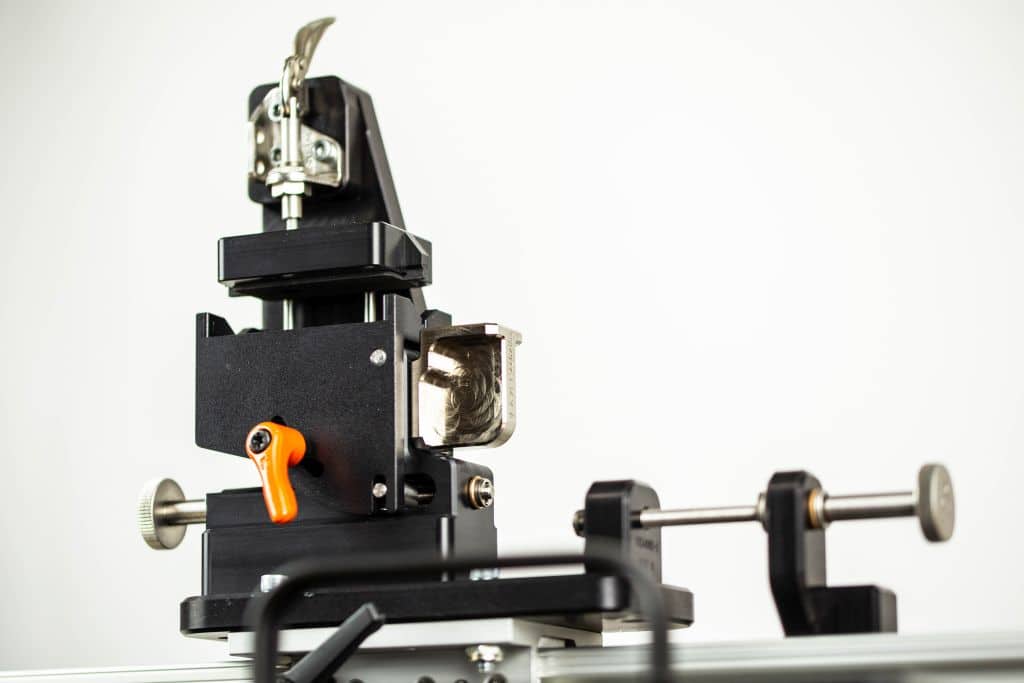

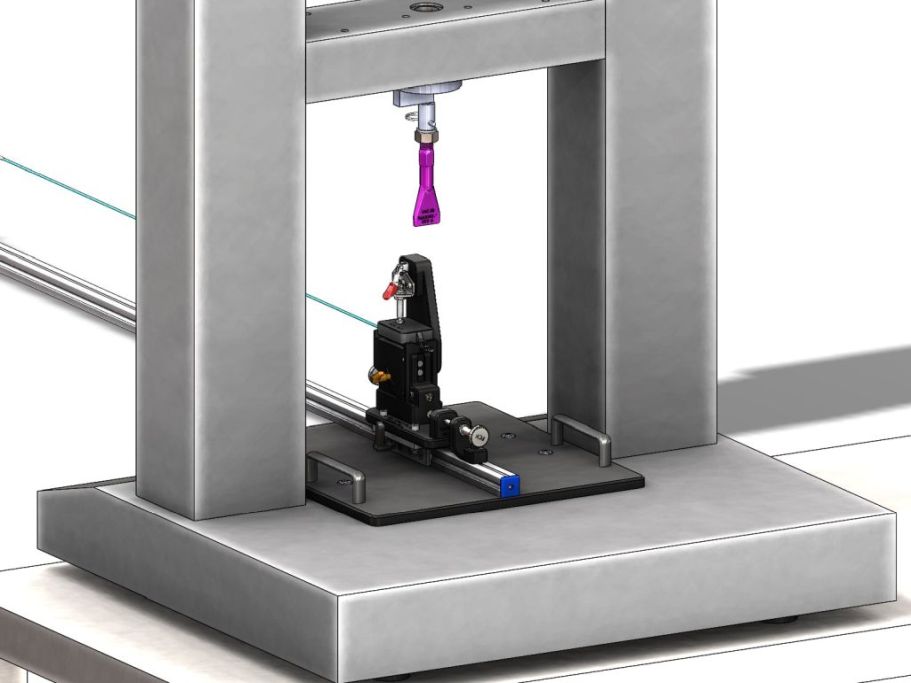

Pipeline designed and built a test fixture that is placed in a load testing machine for analyzing the rigidity of the distal tip of a catheter.

TEAM:

Mechanical Engineers

DESIGN TOOLS USED:

SolidWorks

MARKET:

Medical Device Manufacturing and R&D

PROJECT REQUIREMENTS

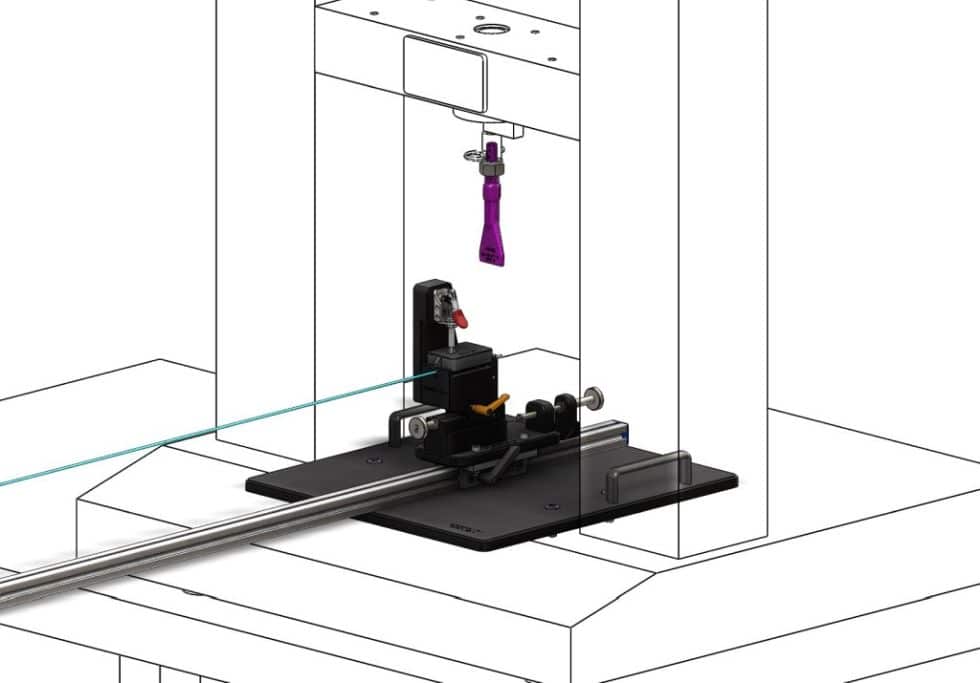

- Isolate the deflection to the distal tip only

- Allow for different moment arm lengths via adjustable position of distal shaft holder relative to the load cell/anvil

- Angle of distal shaft should be adjustable so the distal tip can be set as close to horizontal (normal to load cell) as possible

- Load should be applied evenly on distal tip

SUMMARY OF ACTIVITIES

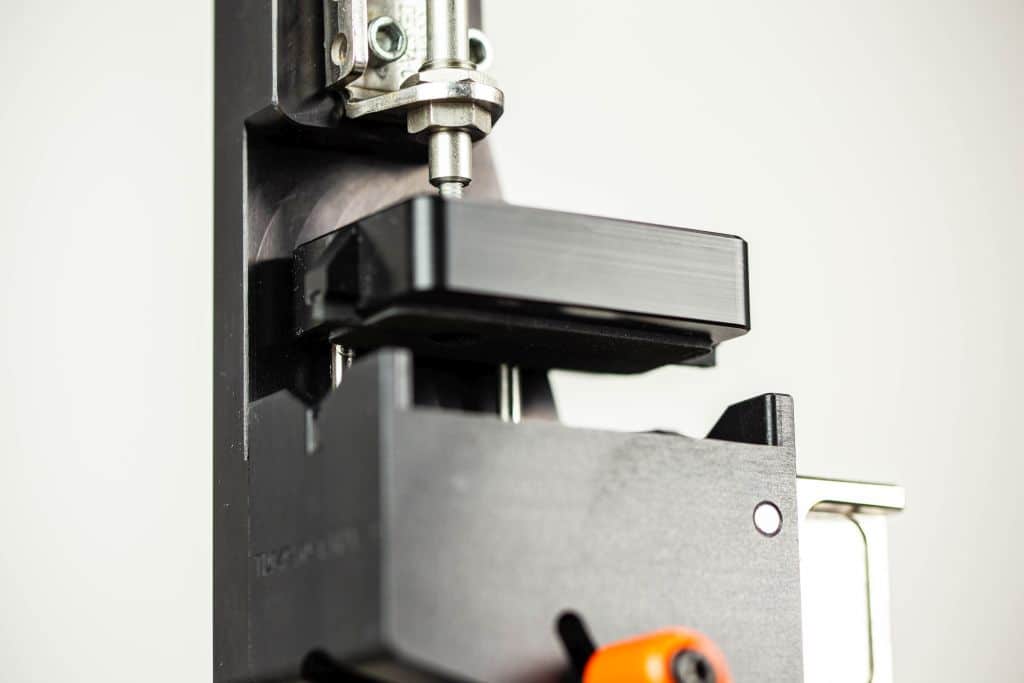

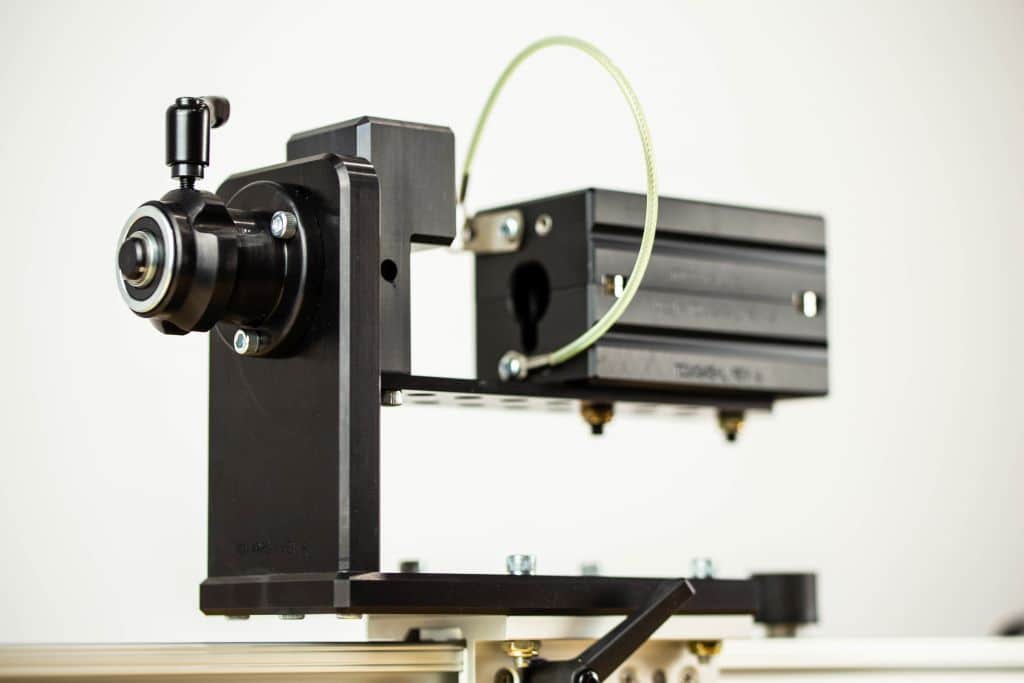

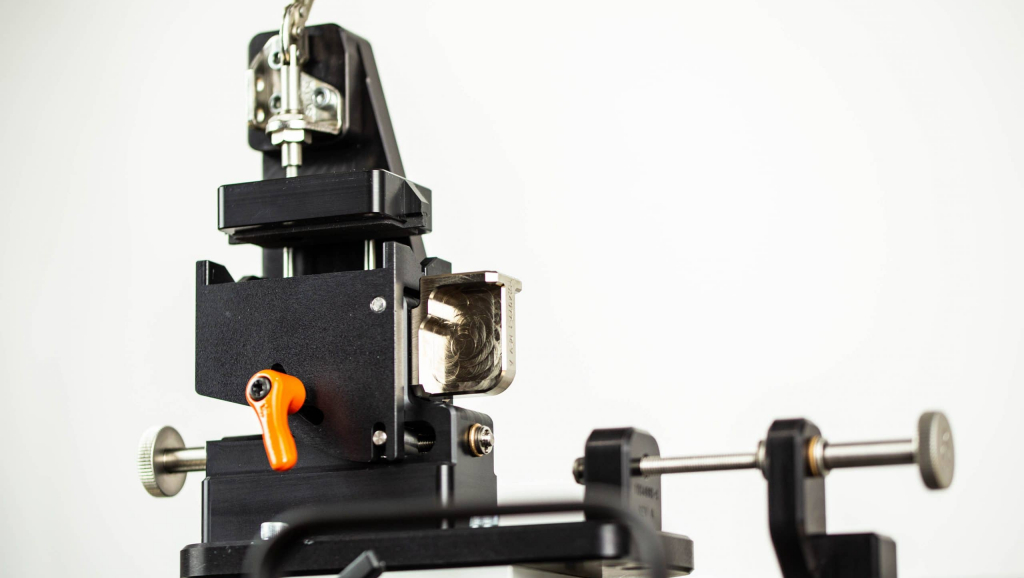

The device handle is placed in the nest of the catheter tip deflection fixture and allowed to freely rotate while the distal shaft area is grasped by a clamping feature. The fixture was designed to maintain a straight catheter shaft so that the distal tip can be more easily aligned with a force probe. After being secured, the distal shaft area is pivoted up and down as needed using the integrated gauge block to align the distal tip to a perfectly horizontal position. The entire catheter tip deflection fixture can be used in conjunction with a typical Instron test frame.

The position of the clamping block on the catheter tip deflection fixture is adjustable using an included adjustment screw; this further facilitates aligning the distal tip with the anvil. This specially-designed anvil is then used to generate a force vs deflection curve while bending the catheter’s distal tip. Activities performed during development included preliminary design, internal design review meetings, detailed design, multiple design review meetings with the customer’s team, final design, manufacturing, assembly, internal test and validation, delivery, and customer test/validation/measurement systems analysis (MSA).

Does your team need help with test fixture design, custom equipment, or automation? Let’s talk!