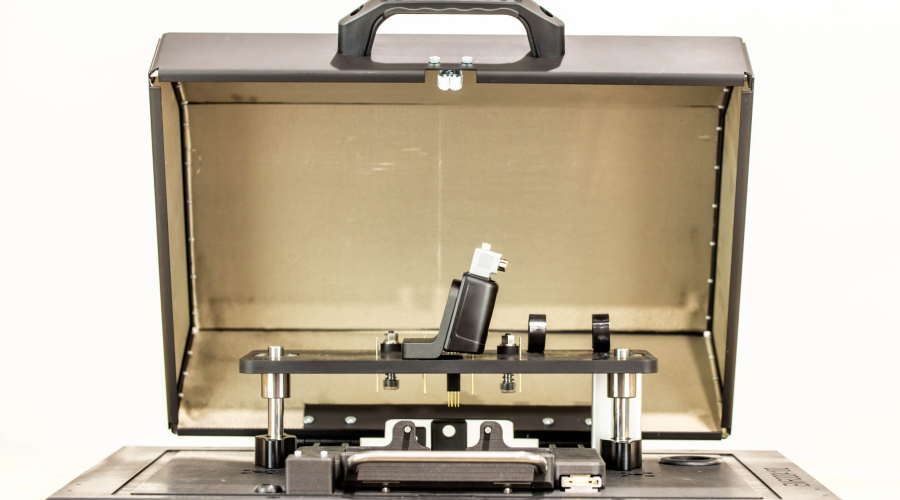

PCB TEST FIXTURE

ELECTRONICS TEST FIXTURE SUMMARY

Pipeline developed PCB test fixtures to facilitate installation and functional verification of firmware onto circuit boards in a consumer electronics device.

TEAM:

Mechanical Engineer

DESIGN TOOLS USED:

Solidworks, 3D Printing

MARKET:

Consumer Products

PROJECT REQUIREMENTS

- Test up to 4 devices at a time

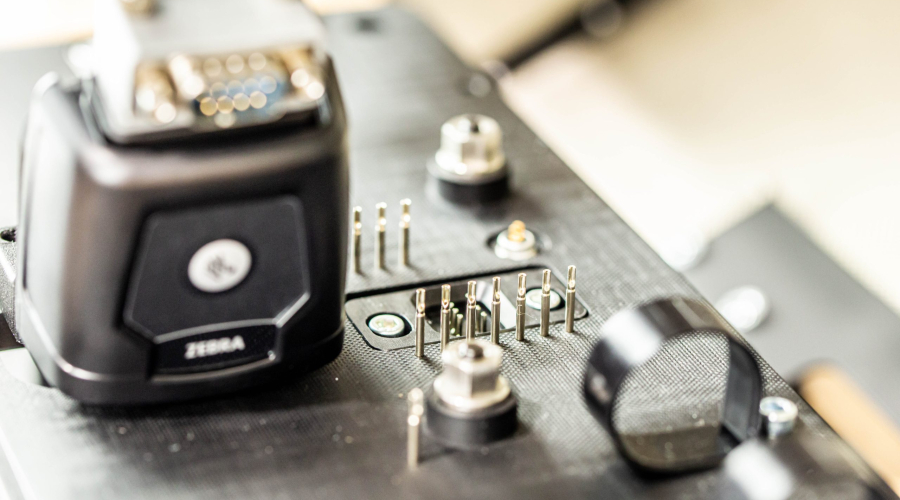

- Facilitate precise mechanical/electrical contact between PCB contacts within the device’s housing and pogo pin probes in the test fixture

- Read barcodes from the device

- Shielding to prevent electrical interference with the testing

- Automated motion control of the test platform to the DUTs

SUMMARY OF ACTIVITIES

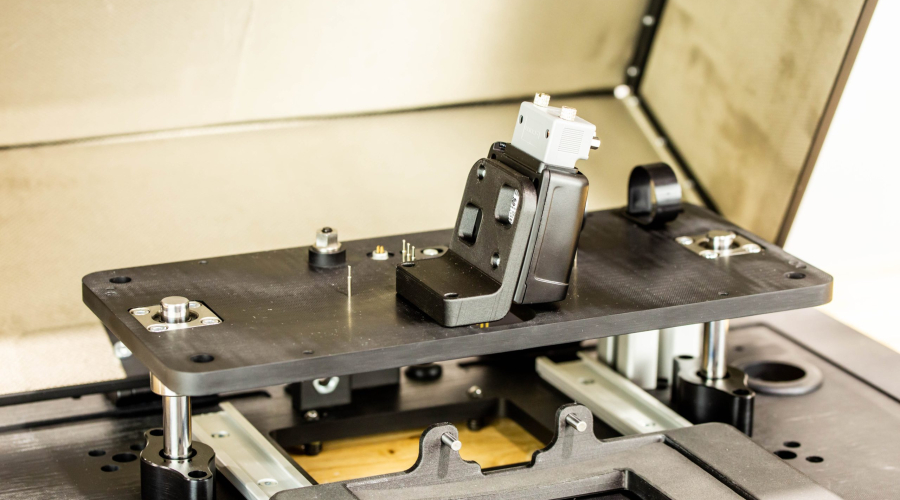

Two PCB test fixtures were developed: one to install firmware onto a circuit board and another to functionally verify the installed firmware. One of the challenges with this project was that the PCBs were already fully installed within the plastic enclosure, severely limiting the access to the contacts on the PCB. Very precise and repeatable mechanisms were incorporated to allow the pogo pins in the test fixture to travel through narrow air vents and touch off on the PCB contacts within the housing.

The fixture that functionally verified the device included an array of capacitive touch probes actuated individually by pneumatic cylinders. The programming behind the PCB test fixture actuated each probe in a pre-defined pattern to ensure touch sensitivity on the device’s screen worked, and that the appropriate software action was taken once the screen’s surface had been touched.

Pipeline designed the mechanical fixtures using Solidworks, procured all BOM items, assembled and functionally validated each before shipping to the customer. This turnkey process is typical for Pipeline, delivering the custom test fixtures or manufacturing equipment ready to use as opposed to only design files that the customer then has to procure, build, and qualify.