VISION INSPECTION SYSTEM

VISION INSPECTION SYSTEM PROJECT SUMMARY

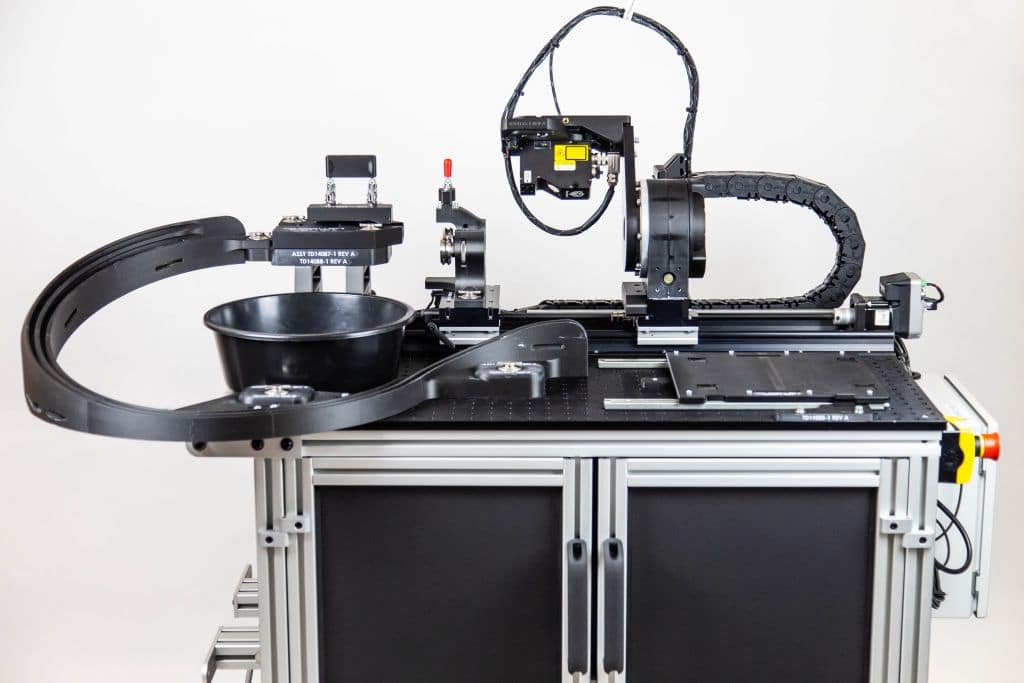

Pipeline Design & Engineering created an automated vision inspection machine to measure shaft RPM, torque, pressure, vibration, straightness & length. See video below.

TEAM:

Mechanical Engineers, Software/Control System Engineer, Electronics/Cabling Engineer, Machinist, Assembly technician

DESIGN TOOLS USED:

SolidWorks 3D CAD

3D printer

MARKET:

Medical Devices

PROJECT REQUIREMENTS

- Measure shaft RPM, vibration, straightness, torque, and pressure

- Be modular to accept multiple devices

- Automated with simple UI for repeatable inspection

- Turnkey system fully self contained on a cart

SUMMARY OF ACTIVITIES

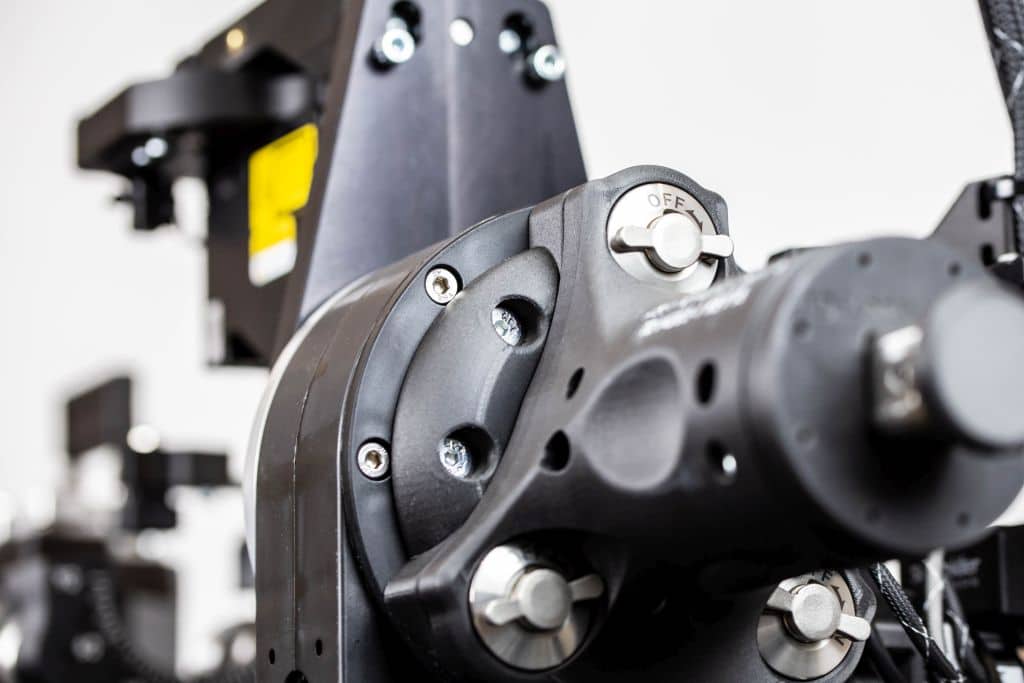

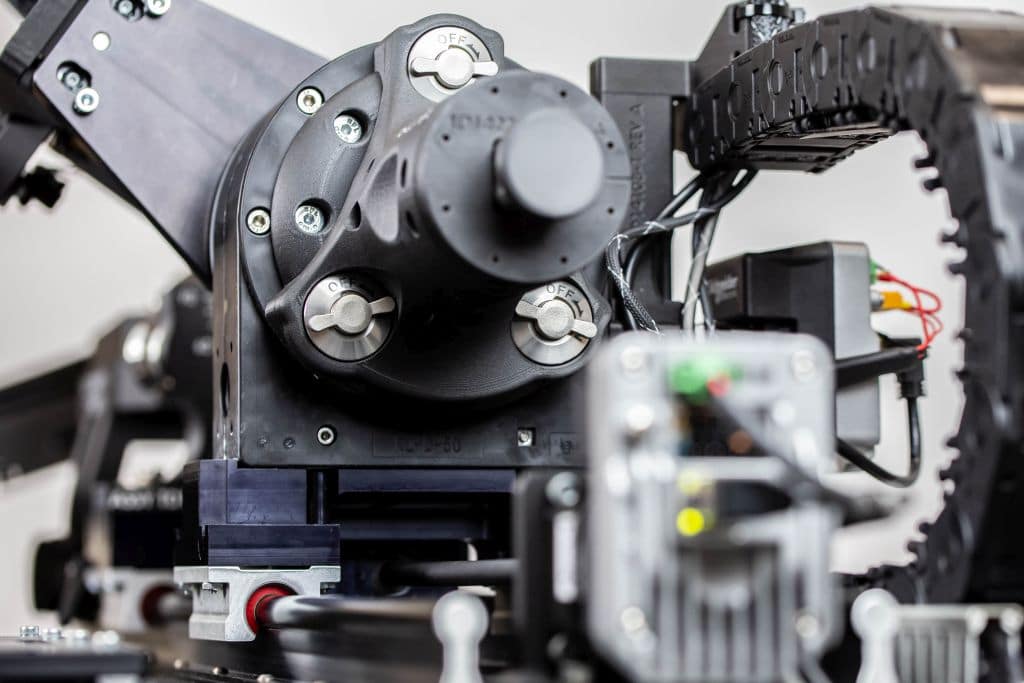

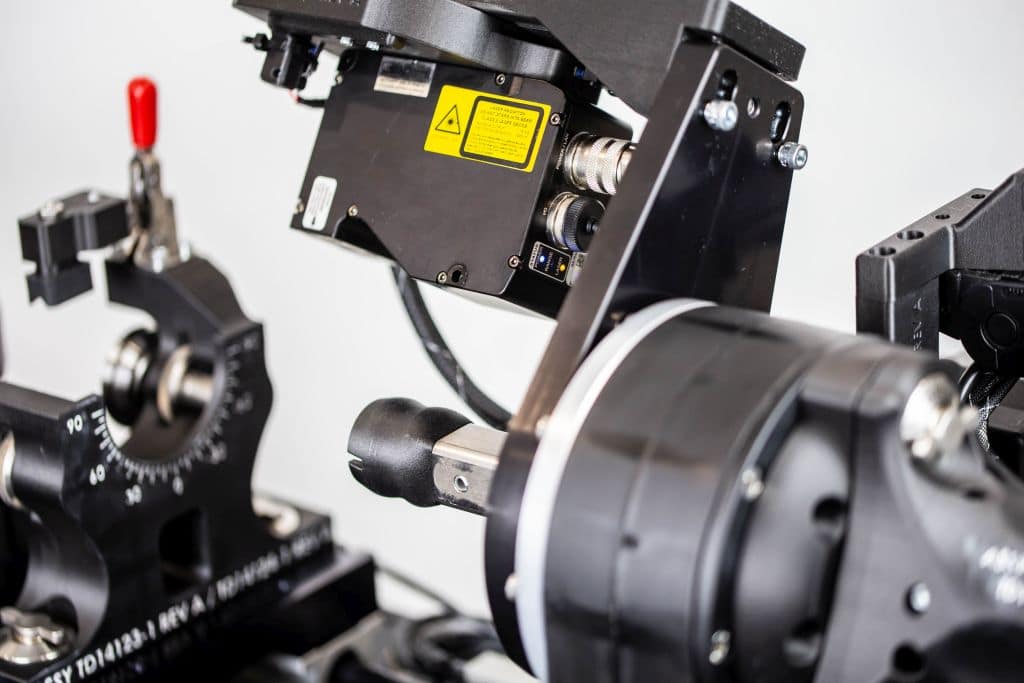

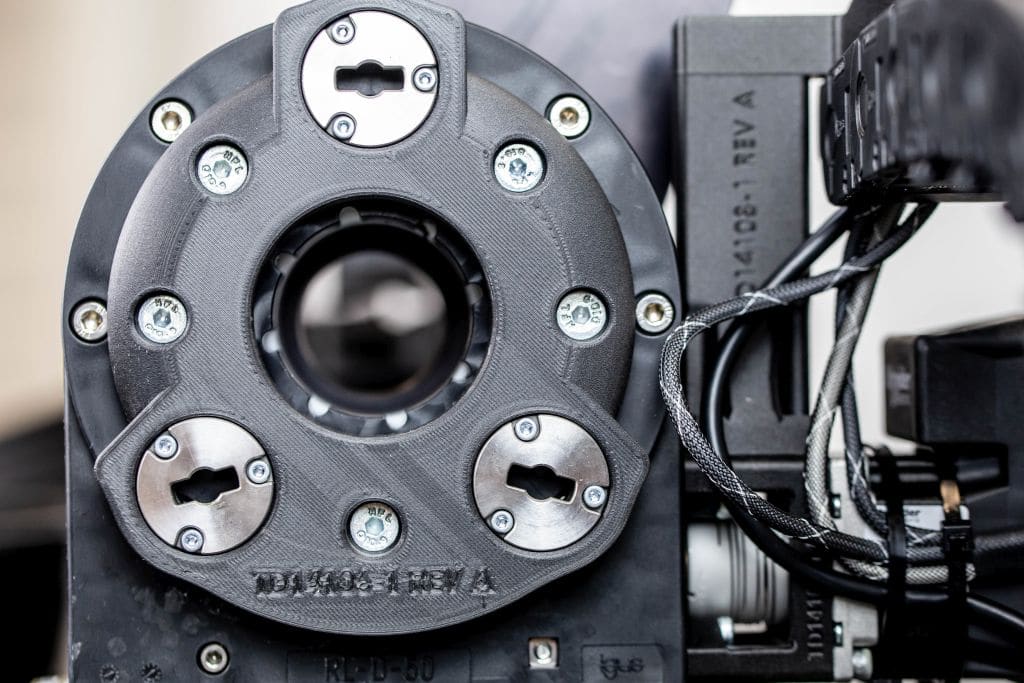

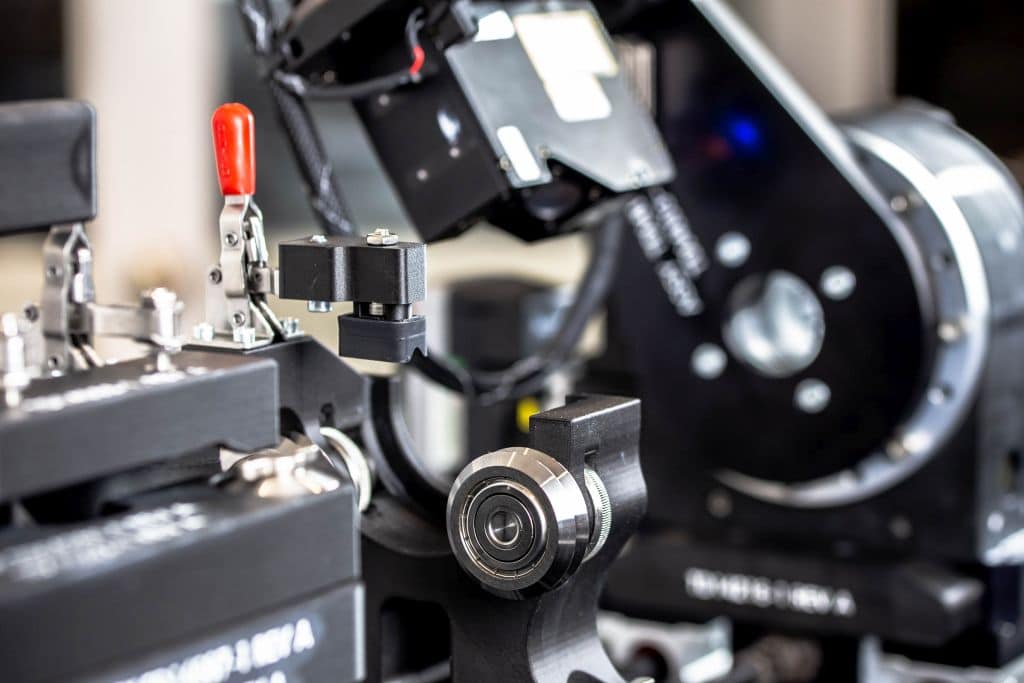

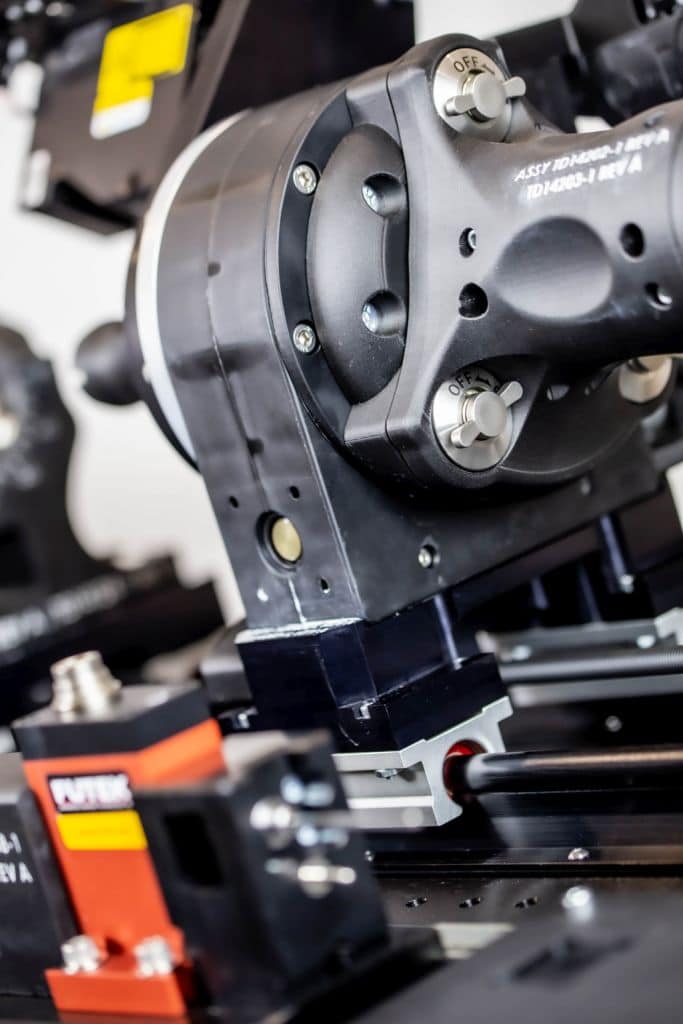

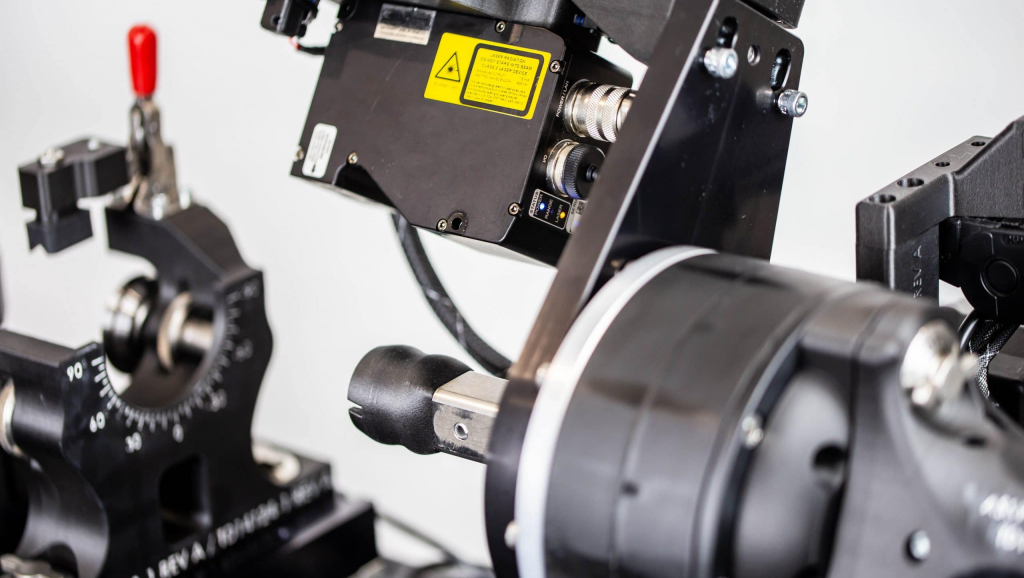

Pipeline developed a visual inspection system for a customer who needed a simple way to functionally verify a large volume of devices during their R&D stage. Extensive custom mechanical design was incorporated to provide the positioning and movement of the various devices and inspection elements (namely the machine vision camera, but also a pressure decay module, rotary torque module, and various device holders). Multiple motors were incorporated along with position switches to ensure movement started and stopped at the intended locations.

Once the mechanical systems were built and validated, the programming was refined so all of the vision inspection system tests were performed automatically with the simple press of a button from the operator. This ensured that the tests were performed in a repeatable manner each time, and thus no variation was introduced into the testing protocol by operators. Pipeline also developed custom software in LabVIEW to facilitate this automation.

Need help with test fixture design, custom equipment, or automation? Let’s talk!