VOCERA B3000 BADGE

PROJECT SUMMARY

Vocera’s current communication product was revamped to include new features and functionality. Pipeline provided much of the design & engineering to make the assembly optimized for manufacturability.

TEAM:

Mechanical Engineers

DESIGN TOOLS USED:

SolidWorks 3D CAD

MARKET:

Commercial Product

PROJECT REQUIREMENTS

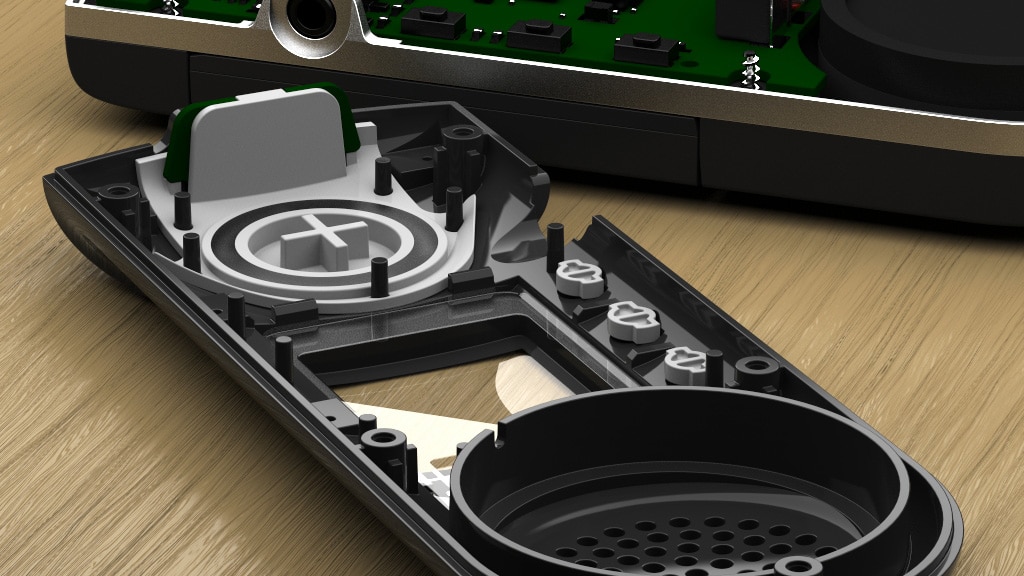

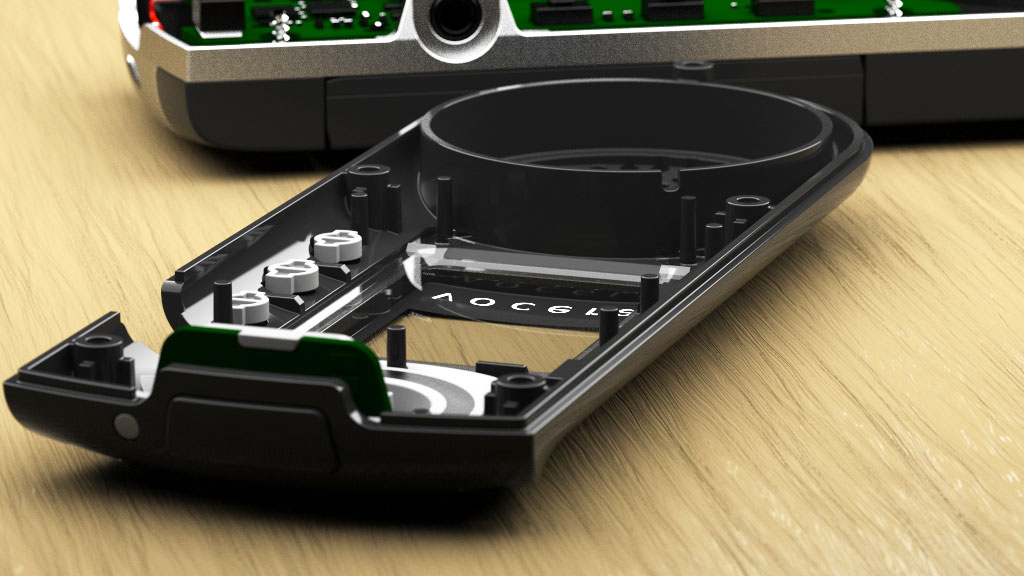

- Organize and maintain full CAD assembly during mechanical development

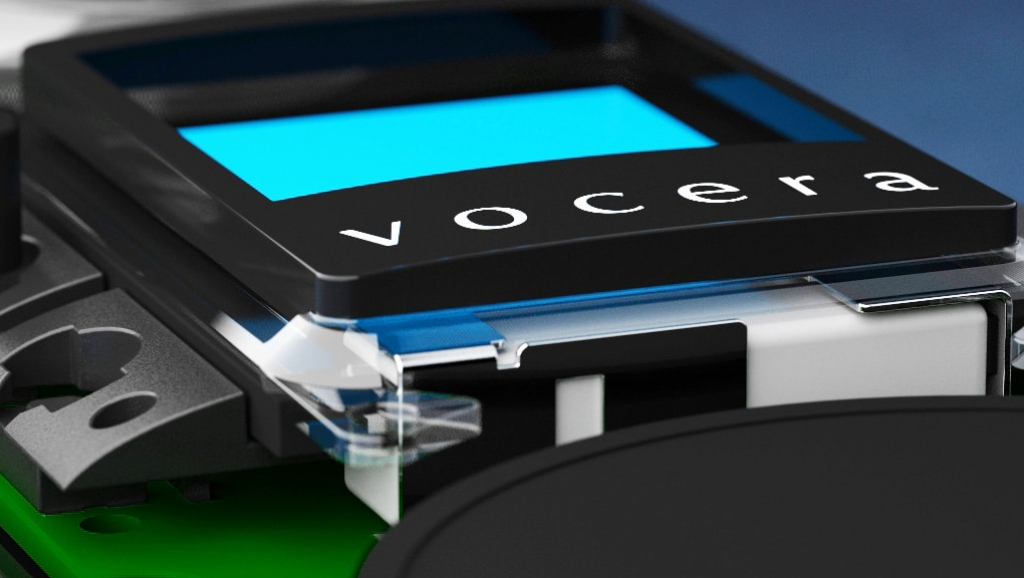

- Integrate window on front casing for OLED visibility

- Redesign call button mechanism

- Modify speaker grill to match Industrial Design concept

- Design all elements to be injection molding friendly

SUMMARY OF ACTIVITIES

Vocera’s B2000 badge had been a wonderful success in the health care arena, and the company was now ready to focus on its successor: the B3000. Sporting a brand new OLED screen along with enhanced ergonomic buttons, the B3000 was a highly anticipated upgrade to its predecessor. Pipeline was asked to provide mechanical design support to the redesign effort by accomplishing the tasks listed above.

As with many commercial products, aesthetic was very important in this design. Vocera had already developed the design aesthetic. Pipeline incorporated complex 3D surfacing techniques in CAD to produce seamless curvature and feature throughout the model components we worked on. This type of 3D modeling is a specialized skill that Pipeline was able to offer, creating organic-looking geometry that would not be possible with traditional “block” modeling.

Our areas of responsibility included the entire upper casing, as well as the call buttons, OLED retainer, and polycarbonate window. Advanced CAD techniques were used to layout these components and ensure proper fit without interferences. A variety of surfacing skills were used for this portion, as well. Ultimately, Pipeline was able to deliver a fully redefined assembly of the parts assigned us that met all of the client’s requirements, and accomplished it in approximately 3 weeks.