SPELLBINDERS

Design Solution

SPELLBINDERS PROJECT SUMMARY

Pipeline reworked a concept design to be injection moldable

PROJECT DATA

TEAM:

Industrial Designer, Mechanical Engineer

DESIGN TOOLS USED:

SolidWorks 3D CAD, Photorealistic Rendering

Finite Element Analysis

MARKET:

Arts and Crafts Industry

PROJECT REQUIREMENTS

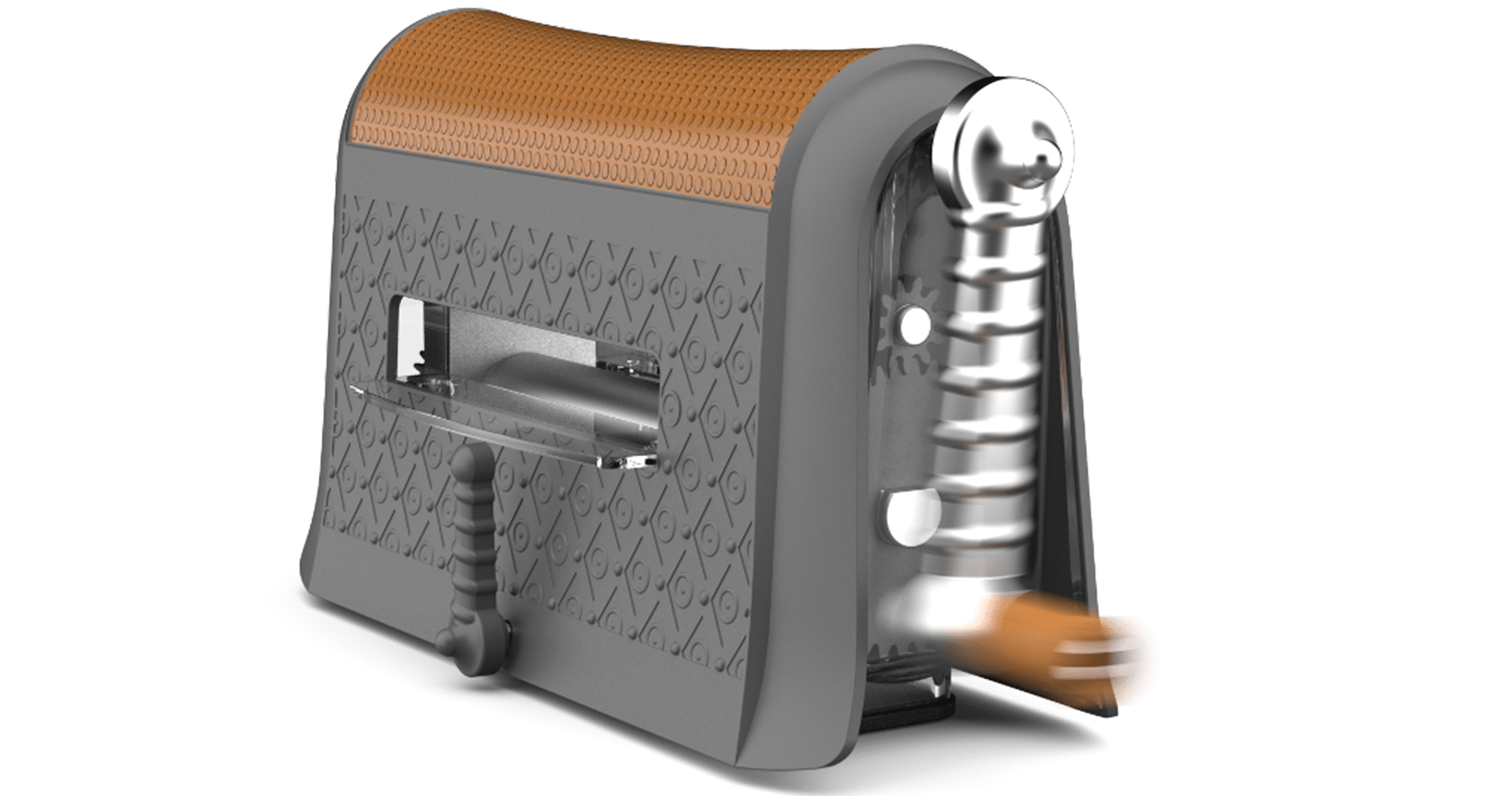

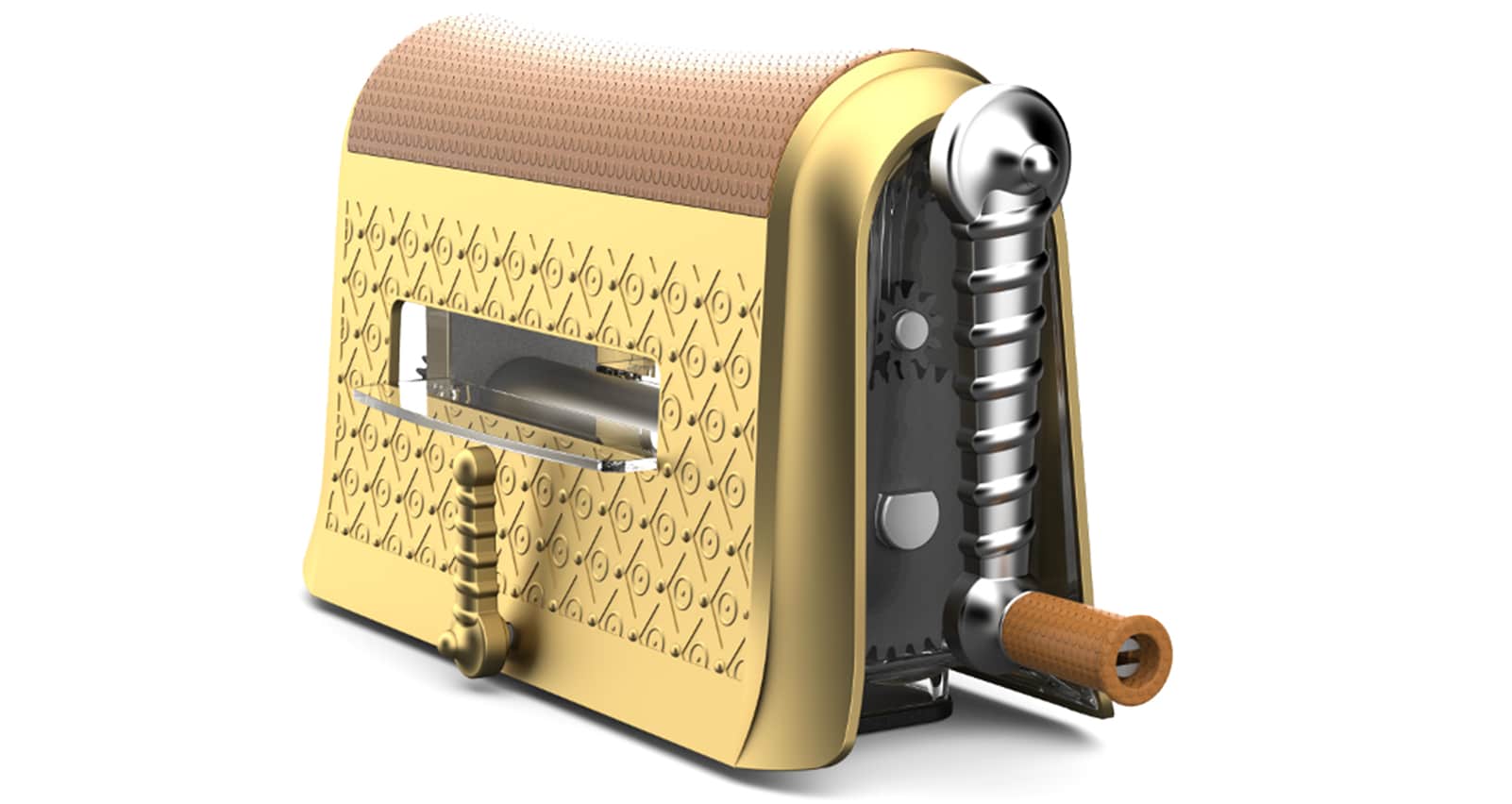

• Work with existing aesthetic concept

• Incorporate complex surface modeling techniques to define mold-friendly geometry

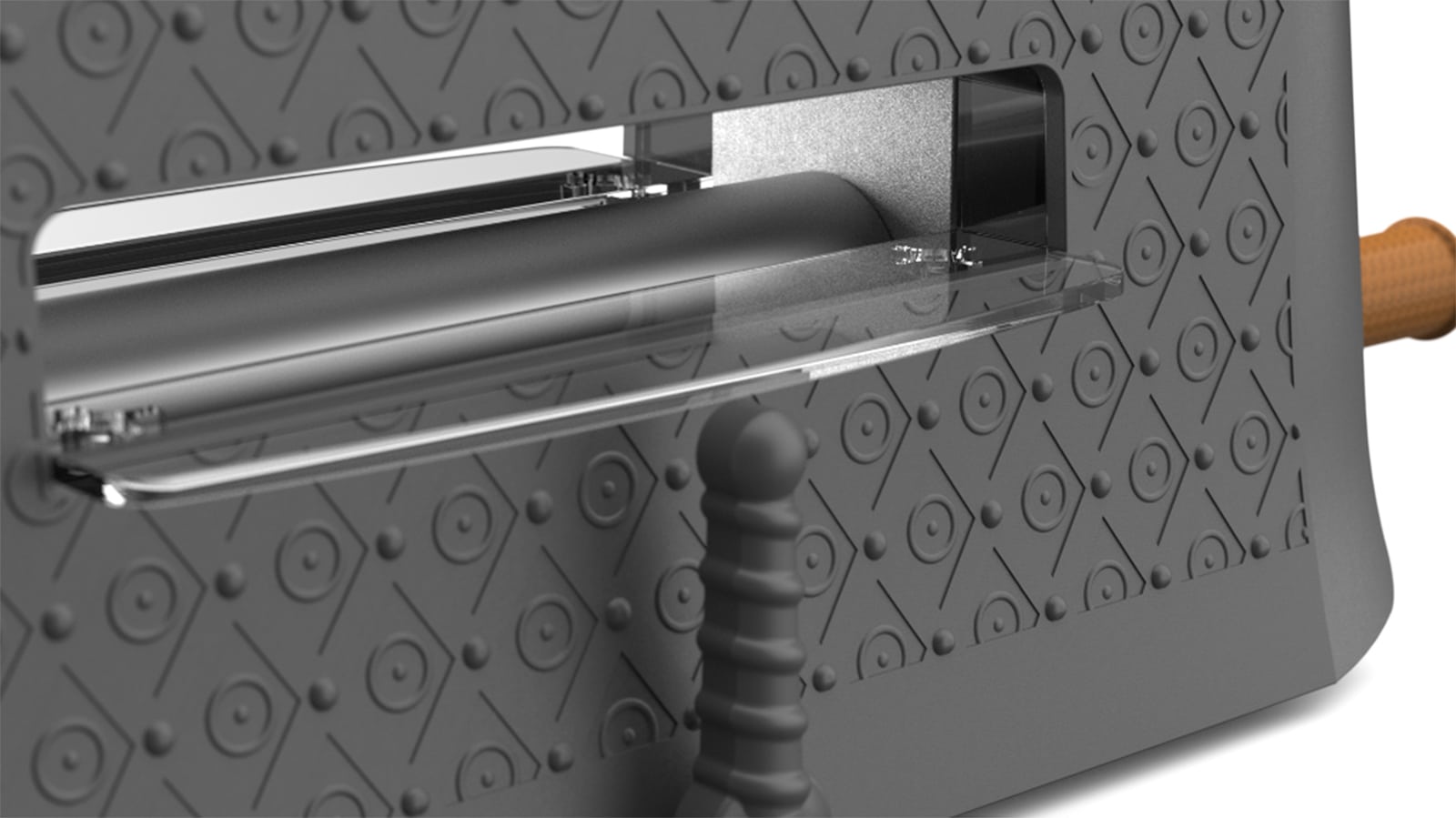

• Rework handle for increased robustness while maintaining aesthetic design language

• Define layout and assembly protocols for component installation

SUMMARY OF ACTIVITIES

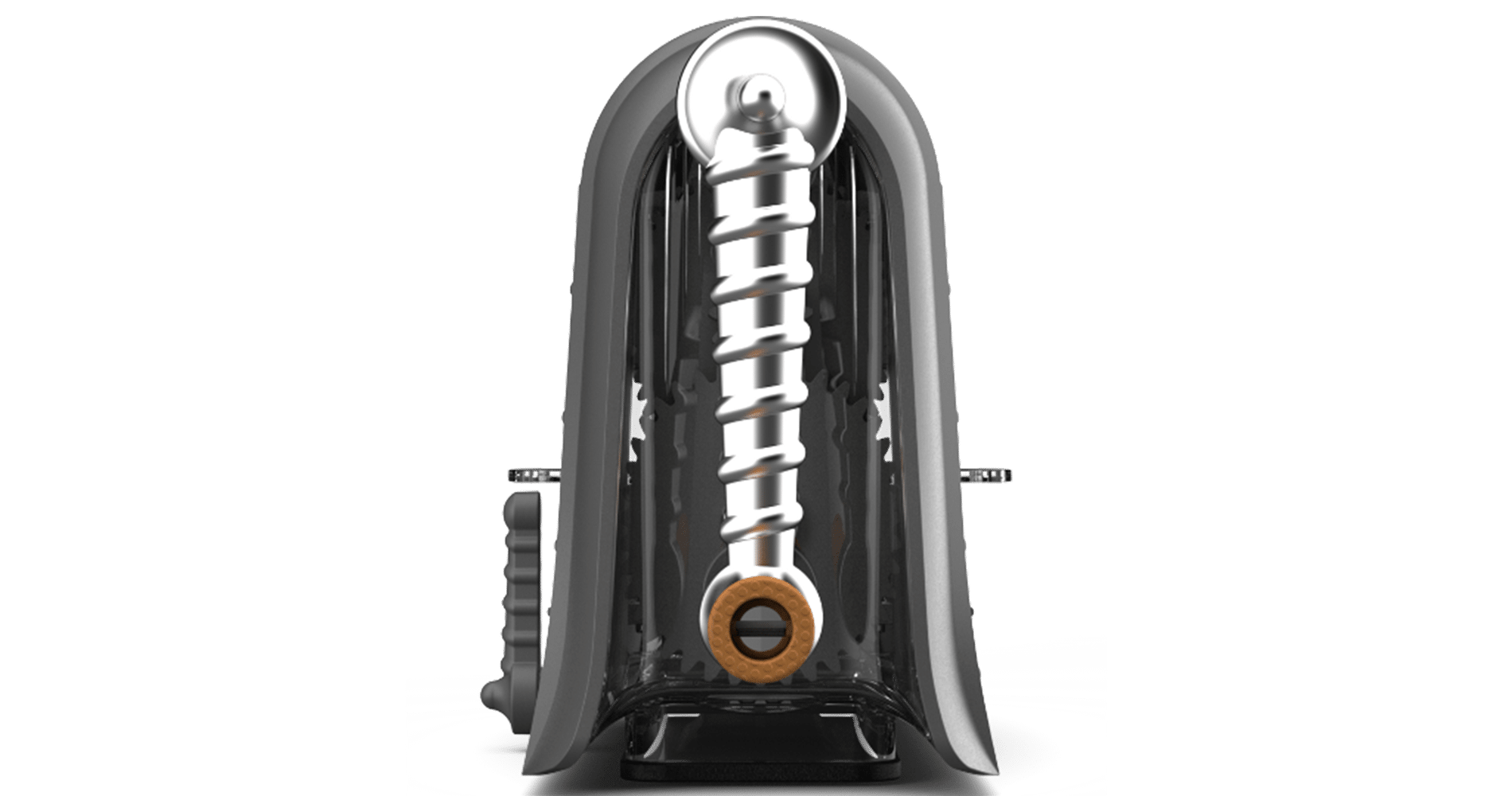

An existing customer came to Pipeline with a new design for the customer’s latest product, a roller press for the craft industry to cut, emboss and press paper, metals, fabrics and plastics. The aesthetic concept was completed, but it was not designed with manufacturing in mind, and needed to be reworked to be injection moldable. Additional design work was needed on the handles, as well.

Using the aesthetic model as a basis, Pipeline developed from scratch the entire housing, base, suction cup, and handles. FEA was performed on the handles to ensure they would hold up to the forces applied during use. The engineering team also made several key modifications to the design to facilitate simple assembly for the now mold-friendly design. A variety of photorealistic renderings were also created to aid the customer in choosing a final color scheme for production.